Building a Custom Solution for Farming

Long-Range Communication to Support Autonomous Micro-Tractors

PROJECT REQUIREMENTS

- Scaleable differential I2C communication

- Integrated power and data

- A hot swappable solution

FEATURED PRODUCTS & SERVICES

Mission: Support Small Farms

Farmhand Automation is on a mission to “help small farmers grow the local food movement to the next level.” As climate change continues to impact farming around the world, farmers need access to affordable, cutting edge technology that enables them to scale their passion and build a diverse portfolio of traditional farming, hydroponics and local farming without accruing massive amounts of debt to do it.

As founder Alex Jones explains, “I got into agtech because I wanted to be an organic farmer in my 20’s and after all the training and working with several farms it was easy to see that the system does not work in the favor of small independent growers across the United States. I’ve been passionate about making a dent in that problem through IoT, software and AI.”

While developing autonomous micro-tractors to help small farmers grow their business, Farmhand Automation realized they needed a low cost, open source CAN/Modbus alternative.

Jones explains, “We’re really hoping to help develop a new standard of communication in robotics and automation using easy to use open source tools that anyone with Arduino experience can get their hands on. We could have gone with more traditional solutions but we really wanted to turn this challenge into an opportunity to support the open source community and encourage people to think big.”

The Farmhand crew shows off their microtractor.

“We’re really hoping to help develop a new standard of communication in robotics and automation using easy to use open source tools that anyone with arduino experience can get their hands on..."

Journey: Building a Hardware Solution for Plug-and-Play Long-Range Communication

To create the initial prototype for their idea, Farmhand had been working with SparkFun’s Differential I2C board. When they realized adding the ability to daisy chain the boards together would create a solution close to other industrial standard communication methods and reduce the overhead of needing to translate sensor data and commands into CAN format and back again, while still remaining compatible with open source I2C sensors, they reached out to SparkFun.

Through SparkFun’s services offerings, SparkFun designed a custom board to meet Farmhand’s needs.

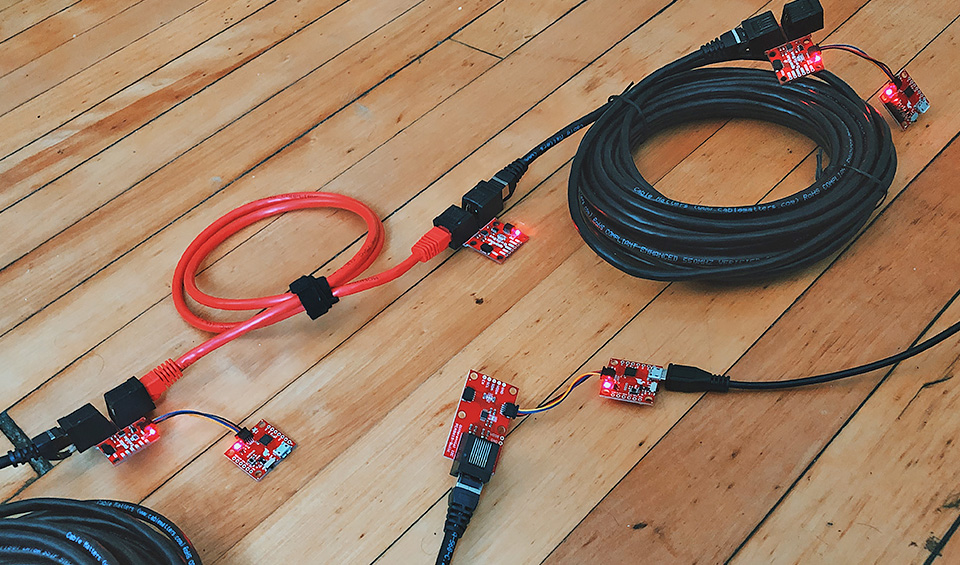

By collaborating with SparkFun, Farmhand Robotics was able to turn their vision into reality. The QwiicBus MidPoint and QwiicBus EndPoint delivered on just what Farmhand was looking to create - scalable, differential I2C communication across multiple devices that integrates power and data communication over ethernet. As an added benefit, Farmhand doesn’t have to write custom drivers, everything is plug-and-play.

“The biggest benefit this project has to our system is that we can have secure data connections with open source sensors that already have Arduino libraries and drivers written, many by Sparkfun,” states Jones. “That was really the key for us, we knew the sensors we wanted to use, but as soon as you need to communicate over long distances in noisy environments things get complicated. The Qwiic Midpoint is going to solve a lot of that headache.”

With the QwiicBus MidPoint and QwiicBus EndPoint boards in hand, Farmhand Automation can now focus their efforts on bringing expanded automation and agtech to local farmers through autonomous micro-tractors and more.

As for working with SparkFun to design the board, Jones says “It can’t be understated the impact this has for us. The Sparkfun team has been great to work with. They are data driven, listen to our needs and collaborate really well.”

Close-up view of micro tractor robot.