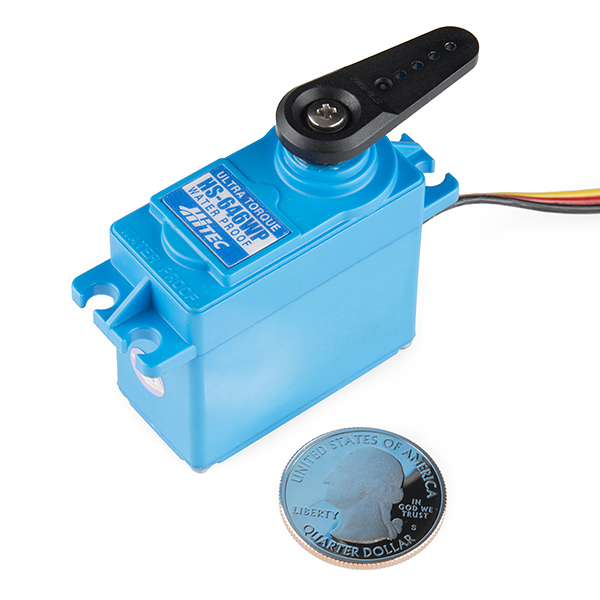

Servo - Hitec HS-646WP (Standard Size)

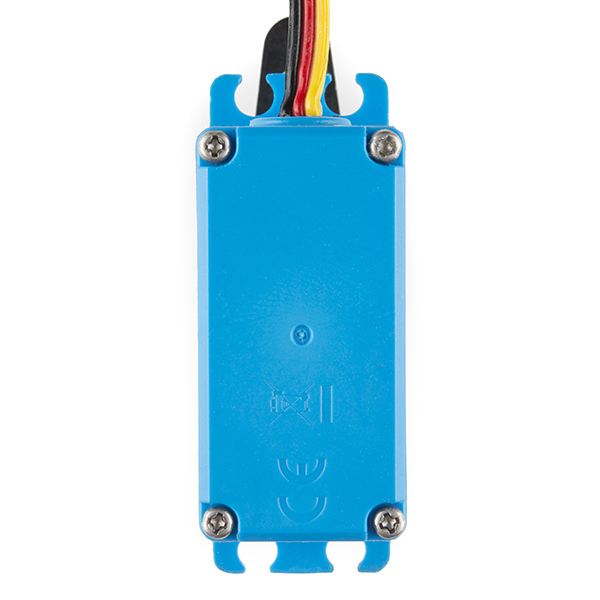

This unique motor is the Hitec HS-646WP servo. What separates this servo from the rest is that it is waterproof with a IP67 (Ingress Protection-67) rating! The HS-646WP is able to take in an impressive 7.4 volts and deliver 161.1 oz-in. of maximum torque at 0.17 sec/60°, and those are numbers you can rely on!

This high quality servo is perfect for your mechatronic needs and if you are looking to get into robotics, this is where to start. The HS-646WP servo comes standard with a 3-pin gold plated power and control cable and all hardware listed below.

Note: The HS-646WP is actually slightly thicker than its other standard size cousins. Therefore, it is NOT compatible with the Actobotics Servo Mounts or ServoBlock Kits.

- 1x HS-646WP Servo

- 1x Four Point Horn

- 1x Double Arm Mega Horn

- 1x Circle Mega Horn

- 2x Single Arm Horn

- 4x Rubber Grommets

- 4x 2x15mm Phillips Screw

- 4x Brass Eyelets

- Voltage: 6.0-7.4 Volts

- Torque: 133.3/161.1 oz-in. (6.0/7.4V)

- Speed: 0.20/0.17 sec/60° (6.0/7.4V)

- Direction: Clockwise/ Pulse Traveling 1500-1900usec

- Rotation: 180°

- Dual Ball Bearing

- 3 Metal Gears & 1 Nylon Gear

- 3-Pole Ferrite Motor

- C1 Standard Spline

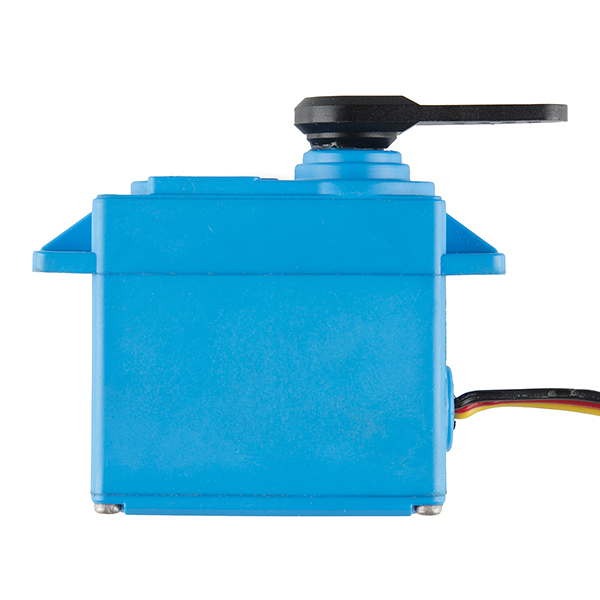

- IP67 Waterproof Rating* 41.9 x 21 x 40mm

- Wire Length: 180mm

- Weight: 60g

Servo - Hitec HS-646WP (Standard Size) Product Help and Resources

Servo Trigger Hookup Guide

March 26, 2015

How to use the SparkFun Servo Trigger to control a vast array of Servo Motors, without any programming!

Hobby Servo Tutorial

May 26, 2016

Servos are motors that allow you to accurately control the rotation of the output shaft, opening up all kinds of possibilities for robotics and other projects.

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Competent - You may need an understanding of servo motors and how to drive them. Additionally, you may need some fundamental understanding of motor controllers.

See all skill levels

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

For those interested: data sheet states this is rated at IP67, which according to Wikipedia is tested at 1m depth for 30 minutes.

What happens after 30 minutes? Does the O ring give allowing water to flow into the base?

I would think not. Many such things are vastly under-rated, this could probably hold for quite a bit longer. Even if the o-ring fails, the board appears to be potted: it would likely withstand water indefinitely.

Every single review of this servo focuses on the waterproof feature, which is not important for me... Is there anybody who has tested it and can tell me something about its performance? I mean, what about its precision or repeatability? Current consumption? They're suposed to work fine directly connected to 2-cell Li-Po (7.4v nominal), but what if the battery is large anough to keep for a long time near its full charge voltage (8.4 max)? Do they get hot or burn?

I'm actually building a medium size hexapod robot, so I'm looking for a good and not so expensive servo, near 9Kg*cm torque. I'll use Li-Po batteries, and I was looking for a HV replacement for the HS-645MG, beacause I want to avoid using BECs. Is it possible that, besides the waterproof feature, this is one of the best analog servos that Hitec is offering? And costs a little more than 30€! Where is the trick?

Are the ratings (whether IP67 or "Wikipedia-published") good while the servo is actually rotating?

yes

The datasheet says this servo is rated for 4.8-6.0V but the product page says it is rated for 6.0-7.4V. Which one is correct?

6.0-7.4V. datasheet is being updated.

Sir (Sparkfun Engineer),

1) I notice the specs say "Direction: Clockwise/ Pulse Traveling 1500-1900usec" - does that mean it will not rotate in reverse?

2) Can you remove a stop to make the servo rotate 360 degrees?

3) I know the US is still stuck with the Imperial measurement system but could you please also include the metric equavilents for all specifications (for example torque)? - for the benefit of the rest of us (namely most of the rest of the world).

1) this is just a way of saying what pulse range is clockwise. of course going from 1900-1500 would be counterclockwise and yes, it can rotate in reverse. otherwise it would be a one-time-use motor, right?

2) check the video. most likely there is a way. there should be a stop in there that can be removed. check the video at 3:54. there's a pin on one of the gears. it can be removed, but you might need a tool to tap it out, or a drill or arbor press.

3) units are exactly that, a unit that is used to measure another relative unit. converting to and from is not lossy, it's exact. so, you should be able to easily convert between them. we tend to stick with the units the manufacture provides for us.

Robert,

Thank you for answers to points 1 and 2.

Your answer to point 3 can best be described as muddled. Firstly I know what a unit is (I'm an engineer). Secondly, I understand unit conversion (I'm an engineer!!). What you mean by "lossy" (sic) is beyond me. Finally you failed to comprehend and thus answer the question, (i.e. point 3) so your response gave no useful information. The US is one (of a VERY small number of countries) that are still stuck with the Imperial measurement system, the rest of the world (thus a great many of your customers!!!) uses the logical and easy to use SI Measurement system, (commonly known as the metric system).

lossy = the values remain the same when converting back and forth.

I understand that the rest of the world uses the metric system. I understand also that it's more logical. Cases can be made either way, but at the end of the day, we are a US-based company. We tend to use whatever units the manufacturer provides. and if we have a choice, we tend to go for metric.

Re: 3): Not to mention, those of us in the U.S. who would really prefer we use SI measurements, as the old system causes lots of heartaches to us Engineers, like ill-fitting parts, or crashing Mars orbiters.

Got ya covered! It's a maximum of 1.1376 joules at 7.4V ;)

And don't even get me started on the Decimal Mark.

Thanks PocketBrain, - Yes I agree, doing engineering calculations in SI units is a WHOLE LOT EASIER than using Imperial units. I know of one engineer (in the US) who preferres to use Imperial umits (get a load of that) - go figure that one - its beyond me !!!

While I apprecaite "Stilldavids" response, - I thing the units will be g/mm (the imperial units given are oz/inches) as the motor is producing a torque (thus it is a moment). Joules are units of energy, thus not applicable.

I note RobertC is deafiningly quiet on this issue - I wonder if he understands it?

I am sure Robert C understands you perfectly..I don't think you understood him...

They sell hundreds, if not thousands of products. While it may seem trivial to you, converting all those numbers to the system YOU prefer is a lot of work. Instead, as he pointed out in English (might be US English, but I think it translates fine to UK English), is that they prefer to use the units the manufacturer provides.

The part about 'lossy' was just a polite way of saying (even in British terms), 'you can do it yourself and get the same results I would'. Especially since with this crowd, if they were to make a mistake converting, many of you (I'm looking at you!) would go all ape-shit over it.

Can't please all of the people, 'specially when most of them think they're experts....

Sciencez,

1) Straight from Wikipedia "lossy" compression is a data encoding method that compresses data by discarding (losing) some of it. In other words no loss of accuracy in unit conversion. Something I'm sure you knew.

2) Second result on Google http://www.convertunits.com/from/oz-in/to/N-m. I think RobertC understood you just fine but was encouraging a DIY approach.

I personally prefer SI but have no problems converting the relative data for myself since no data sheet has all there units cross converted to all possible units.