Way back in September 2011, we caught wind of and featured some amazing robotics projects from a dad-and-daughters team. Their two robots - modeled after modern tanks and the Mars Rover - were impressively executed (and included a slew of SparkFun parts); turns out, we weren't the only ones who noticed, and not long ago the New York Hall of Science contacted Beatty Robotics (their official name) about constructing a brand new, updated and functioning Mars Rover for their Mars exhibit - and they agreed!

According to their shop blog the Mars Rover, which is in the final construction and testing phases, is constructed of over 700 electrical components, aluminum parts, and other pieces that they purchased, made by hand, and/or machined on their homemade CNC Mill. In addition to the NASA-style six-wheeled rocker-bogie suspension system and the solar panels, the new Mars Rover is equipped with an infrared camera, a thermal array sensor, eight sonar sensors, and other technology. Using special control software that they provided and programmed, kids and other visitors to the center will drive the Mars Rover remotely through the exhibit’s Mars-scape on a mission to find infrared-emitting rocks that may provide evidence of past life on Mars.

Robert, Camille and Genevieve were kind enough to let us share a few of their photos of the project, and discuss their thoughts on some heavy-hitting subjects, like custom Command Sequence software, Clone Wars, and who the next CEO of SparkFun will be (watch out, Nate).

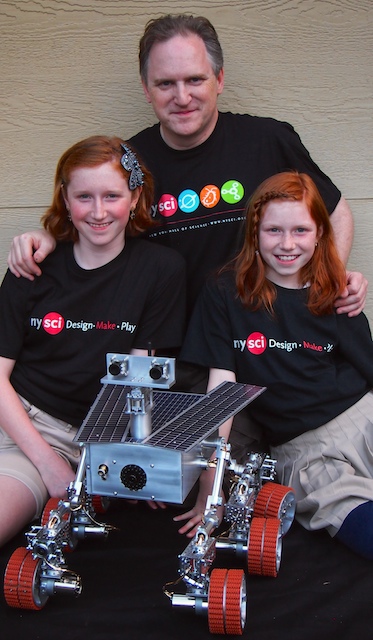

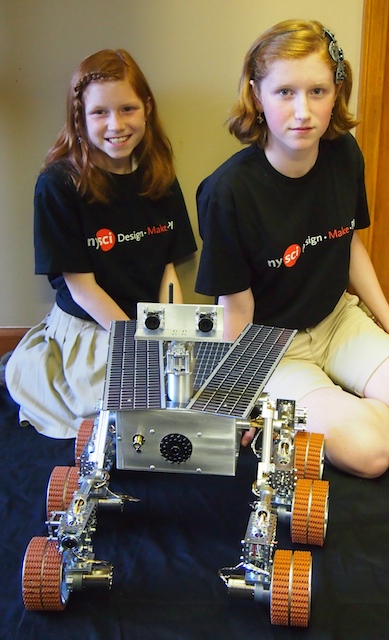

Camille, Robert and Genevieve Beatty with their Mars Rover

Can you tell us a little bit about yourselves and what you do and how this all started?

Camille: When I was 11, I started taking apart calculators, clocks, and TV remote controls to see what was inside. My dad asked me if I wanted to build something myself. We started out creating simple circuits on a breadboard to light up LEDs. Then my dad asked, “What do you want to build next?” and I said, “A robot!” We started out really basic at first and learned as much as we could. I’m 13 now and I’m in 7th grade. We’ve built all sorts of rolling, crawling, flying, beeping, blinking robots.

Genevieve: I was 9 when we started. I was kind of interested when I saw my sister and Dad playing with electronics, but then I got really, really excited when we started talking about building a real robot because we decided to make it look like the 327T / Treadwell droid from Star Wars Clone Wars, which is my favorite show. I watch it over and over. I’m 11 now, in 5th grade.

Robert: Career-wise, I was the founder and CEO of Plex, an Internet software company; I exited the company a few years back to spend more time with my wife and children. Now I’m an aspiring writer of imaginative fiction for young adults. When my daughter became interested in electronics, I was excited to explore that world with her. We learned about sensors, motors, electrical components, microcontrollers, metal machining, and all the rest of it by studying SparkFun.com, arduino.cc, CNC machining websites, and all the other awesome sites that are out there in the DIY community.

How and when did Beatty Robotics become official, and how has it evolved as the girls have grown?

Camille: We wanted to share pictures and videos of our robots with my cousins and my dad’s brothers who live in different states, so my dad suggested we setup a website. He thought it would be a good way for us to learn how to use Wordpress and post articles and stuff. Once we started posting, it turned out that a lot of people liked our robots. People from all over the world write to us, like the other day the Swiss Institute of Technology invited my sister and I to attend their university. But I figure I better finish 7th grade first. :)

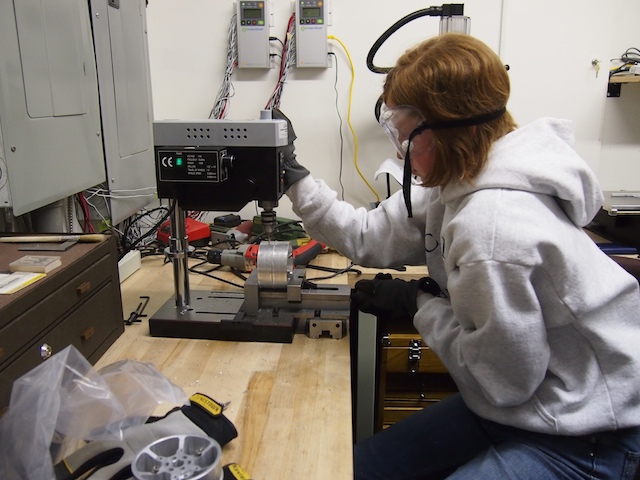

Robert: We knew very little when we started, didn’t know how to solder, or what a common ground was, and had no idea what an Arduino was. We’ve learned a lot together. It’s been fun to see what each girl is most interested in. Genevieve loves to solder and she’s extremely good at it. She’s done 80% of the soldering in most of the robots we’ve built, including the Mars Rover. Camille, on the other, loves machining metal, especially milling, drilling, and tapping, and has become very good at that.

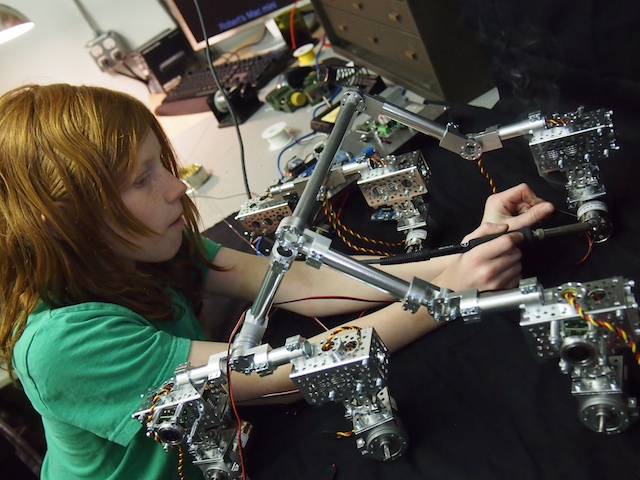

Camille uses the mini drill press to drill holes onto the metal wheels in preparation for tapping the threads.

What was the inspiration for building a Mars Rover?

Camille: We saw the Mars Rovers on the news and we thought it was cool. Then we watched a documentary about Spirit and Opportunity and we shouted: “Dad, we’ve got to build one of those!” So we did. :)

How does your Mars Rover work?

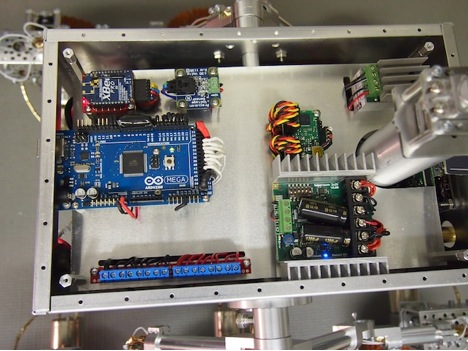

Robert: The Mars Rover runs on an Arduino Mega microcontroller. We use TTL serial to link to the various subsystems. A 2x25A Sabertooth motor controller drives the six motors, and a Maestro servo controller drives the six steering servos. The NASA-style, six-wheel rocker-bogie suspension system, which is the thing we’re most proud of on this robot, is made of aluminum tubes, channels, brackets, machine screws, and other components. When the Mars Rover needs to turn, the Arduino tells the servos at the corner wheels to rotate 45 degrees and then drives all six motors, causing the robot to rotate in place just like the real Mars Rover.

The robot receives commands and transmits its status using an Xbee radio. In order to avoid running into Mars rocks and exhibit walls, the robot is equipped with eight XL-Maxsonar-EZ4 ultrasonic sensors, two on each corner wheel assembly. Temperature and infrared detection is one of the key elements of the exhibit, so the robot includes a thermopile array sensor in order to detect the temperature of what’s in front of it, a green line-generating laser (to visually see where the temperature array is pointed), and a high-resolution infrared-detecting WiFi camera. The robot is also equipped with a voltage sensor to monitor the battery charge.

Our first Mars Rover robot drew power from four SparkFun solar panels, but because this particular robot will be operating in an indoor exhibit we run it on a 10,000mAh 7.4v LIPO battery. We discovered LIPOs when we built our first quadrotors, but now we use LIPOs in every robot we make.

Mars Rover main electronics plate. From left to right, top to bottom: XBee radio, voltage sensor, voltage booster for camera, Arduino Mega, servo controller, power rail and motor controller.

How did the New York Hall of Science end up contacting you about building a Rover for their Mars exhibit?

Robert: The New York Hall of Science has a very cool Mars exhibit, but their existing rover needed a serious upgrade, so they started searching around the internet for options. When they bumped into the video of our first Mars Rover, they contacted us and started asking us about it. One thing led to another, and they asked us to build them a new Mars Rover for their exhibit.

How long did the Rover take to complete, and what materials did you use (any SparkFun parts in there)?

Robert: It took us about two months to build the Mars Rover. We worked on it every day. SparkFun is one of the primary sites we buy our parts from. On this particular project, we went to SparkFun for the Arduino Mega microcontroller, Xbee radios, Explorer breakout boards, Maxbotix sensors, antennas and antenna components, hook-up wire, headers, resistors, blank circuit boards, illuminated toggle switch, screw terminals, heat shrink, Arduino enclosure, and other components. We’ve also bought many of our tools from SparkFun, such as diagonal cutters, safety glasses, and the Hot-air Rework Station. In fact, we’ve bought so many parts from SparkFun in the last two years that we use a stack of about thirty red SparkFun boxes to organize all the various parts we have in our workshop’s inventory.

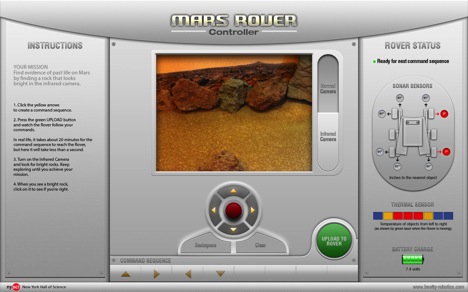

The user interface of the Mars Rover exhibit Control Station

Once the Rover is in place, how will the exhibit function?

Robert: The Mars Rover will operate in an 18’ diameter circular Mars-scape exhibit that includes many artificial Mars rocks. Several of the rocks have an infrared heat lamp concealed inside them. Visitors will sit down at a Control Station (a Mac Mini computer running custom software we developed). The mission is to drive the rover around and search for clues to finding past life on Mars; specifically, to find a rock that emits infrared energy (which indicates the rock may have been formed in liquid water). The visitor is provided a high-resolution video stream and various sensor data as he goes.

To make the robot move, he clicks direction arrows to build a multistep Command Sequence, then clicks the ‘UPLOAD TO ROVER’ button. We could have allowed the visitor to control the robot in real-time using a joystick, but we wanted to simulate the Command Sequence approach used on the real Mars Rover. In real life, it takes 20 minutes for the Command Sequence to reach the Rover on Mars. In our situation, it’s instantaneous. Once the Rover receives a Command Sequence, it executes the commands autonomously, using its ultrasonic sensors to avoid running into obstacles. Once the Command Sequence is complete, the Rover transmits its status back to the Control Station, including the distance to all the objects around it and the temperatures scanned by the thermal array sensor. To the naked eye, the infrared-emitting rocks don’t look any different from the other rocks, but in the infrared camera they appear bright white. When the visitor thinks he’s identified the infrared-emitting rock, he clicks on it. We use blob-recognition in the video stream to confirm that he’s correct and we congratulate him for discovering an important clue to finding evidence of past life on Mars.

Genevieve soldering the wires onto the motors.

Where do you hope this project, and Beatty Robotics, will go in the future?

Camille: Well, for sure, I want to make a super-cool sparkling-LED fiber-optic fabric dress for prom. That would be neat. For the robots, I like small. I’m always trying to make the smallest robot I can, and it gets smaller each time. I’m also trying to figure out how to incorporate nature into my robots. For example, we are building a Snailbot, which is an entire robot inside a real seashell, including an Arduino Nano, little motors, a battery, and an Xbee radio for remote control. We’re going to make the mollusk part of the snail, including the base and head, out of Sugru. The snail’s antennas, which are going to stick up from its head like a real snail creature, are going to be Maxbotix sonars. It’s going to be really cool.

What would be your advice for someone hoping to make their own electronics project, or introduce their children to electronics?

Robert: A lot of parents have contacted us and asked us about this. I normally suggest that they buy an Inventor’s Kit and experiment with it. Then buy the parts to build a small rover - either remote control or autonomous or both - and go from there. My advice to parents for keeping a child engaged is to have the child do the actual work, not just watching you do the work, but doing the work themselves with their own hands.

ReplaceMeOpen

ReplaceMeClose

The Rover's first motion test

There is a particular challenge in the US when it comes to involving more girls in the STEAM education fields, and there doesn't seem to be a clear solution to the imbalance. It seems like you started your robotics projects when Camille started taking things apart - but there are plenty of cases where smart & creative girls don't have the opportunity to start where your daughters did. Do you have any suggestions how parents and educators can reach out to more girls and involve them in projects like these?

Camille: My advice to girls about robotics? Well, first, don’t put the red wire on the ground pin. Bad things happen! :) Seriously, though, I think it would be good to show girls examples of the end product so that they can see some of the neat things they can do. Also, I think the key to involving a girl (or a boy), is that the mom or dad are involved. Young girls want to be with their mom and dad, so if the mom or the dad builds something and keeps the girl involved, she’s going to be interested.

Genevieve: Look at our website and other people’s websites and see all the fun stuff that can be done and then just jump in and start learning about it.

I know it's a ways off, but are you considering careers in electronics fields? (Also - do you want to come work at SparkFun? We could sure use you!)

Camille: If I work at SparkFun, do I get free parts? Then I’m in. But I want to be CEO. :)

Genevieve: I love math and I think maybe I do want to study engineering in college, but I also want to be a writer, so I may need to be a few things.

Camille uses the vertical mini mill to do some machining to modify the laser mount.

What's your favorite part about working on projects like these with your dad?

Camille: Machining. Hands-on stuff. My dad teaches me programming as well, but I’m not a software girl, I’m a metal-cutting girl. I like our vertical mill because I like doing the machining myself, but I like the CNC mill, too, when the part is really complicated. Drawing parts on the CAD system is fun (I use the CNC for school projects now, too). Also, on the Mars Rover, experimenting with the different kinds of lasers was really cool. After doing a series of tests, I selected the frequency/color of the laser (green) and the lens we use (38-degree line generator). But the thing I like the most about all this is spending time with my Dad, and learning about life, and to be patient, and not giving up on something because it doesn’t work at first, and how to puzzle out a solution to a problem. I also really like making new stuff out of old stuff, like one time I got interested in Morse code, so we bought some old telegraph equipment on eBay, but it didn’t really do anything, so we wired it up with Arduinos and Xbee radios and made an Arduino-based wireless telegraph set. Now my sister and I can communicate with Morse code from our separate bedrooms.

Genevieve: Doing all the soldering. I love the soldering. I also like coming up with ideas and drawings for the robots. And I like experimenting to see how things work. On the Mars Rover, I especially liked testing the thermal sensor and the infrared camera in the workshop with my Dad. I also enjoyed pretending I was a kid at the museum using the software that controls the robot. We tried to figure to make it simple and easy to use, but still fun. I’m like the Chief Test Kid.

What's the best thing you've learned from building these projects?

Genevieve: That we can build anything we can think up.

Camille: I think the flow of electricity is amazing. It makes me think that maybe everything is connected, like everything is flowing around in a circuit and coming back around. Nature. Energy. People. Everything. It seems like there is a balance between extremes, positive and negative, whether it’s in machines or in nature.

Genevieve and Camille with the partially-completed Mars Rover

I read on your website that you have a little sister - do you think she'll want to join in on the fun when she's old enough?

Genevieve: For sure. One of her first words was “robot."

Camille: She loves playing with our tools and “helping” us. When we took the picture of Genevieve and I with the finished Mars Rover, we were all laughing because we had a hard time keeping her out of the shot. She’s not even two years old yet, but she wants to be with her big sisters and she wants to be part of things.

Thanks so much for showing us your Mars Rover, Beatty crew! Keep up the awesome work, and good luck with the exhibit!

This is AMAZING - and makes me feel like a failure as a father all at the same time.

You took the words out of my mouth....

Camille, Genevieve and Robert - phenomenal work! You inspire us to keep doing what we do. Thank you! Please come to Boulder, we'd love to show more SparkFun folks your good work. And Camille, if you want to drive for awhile, there are plenty of people here who would like to have you run SparkFun for a few days ;)

Wow! Amazing work. What bright engaged young adults. I was introduced to robotics by my girlfriend at the time and my wife is a brilliant mathematician. Women can do anything they set their minds to. It is wonderful to see such fabulous young scientists. Take a look at the FIRST Robotics competition as well (founded by Dean Kamen)

Very inspiring. I thought my kids might be too young. I love being proven wrong about things like that.

DON'T WAIT TOO LONG!!! I did with my kids..... now they would rather hang out with their friends than be influenced by 'Dad' ...

Awesome work! I'm particularly impressed by the wiring harness. Everything is so neatly tucked away. How about adding some inertial sensors for autonomous navigation?

Awesome work, so inspiring! I guess you used a Lathe fo some pieces, like the tube connectors. Im working in a similar project myself (more simple and with just 6 dynamixel servos in the rocker bogie) and to find those tube connectors are driving me mad. Im from small town in south Spain. Im even considering buying a small matalworking lathe machine. Nice work!

Félicitation les enfants! Je suis épaté par votre superbe realisation

Continuez sur cette voie...

Now I really want to make my own! Amazing job, super inspirational, cannot wait to see what they do next...

Definitely inspiring.. Those girls are going to go far in life. It's so easy to focus on all the bad things that the news focuses on. It is great to see some good going on around here.

Very nice work, very neat and professional, innovative! My ten year old is becoming interested in programming my stamp and Arduino creations, I can only hope he reaches a fraction of your level, Nice work girls!

And to think I was so proud when my daughter could set the time on the VCR clocks that were all blinking 12:00

The two of 'em (my daughters) turned out all right after all. Not geeks but geekish...

The 3 grandsons, on the other hand, are gonna be so Sparkfunned on every birthday, no doubt one of 'em will be shooting for CEO some day.

Bravo bravo, The rover is so well made. Please don't stop building such nice robots.

Looks like they have some Servo City stuff there as well.

Genevieve: http://dlnmh9ip6v2uc.cloudfront.net/assets/2/8/5/7/f/51b0abaece395fd605000000.jpg

Cynthia: http://cdn.c.photoshelter.com/img-get/I00004uoUmnKwDCw/s/750/750/USA-rs-452-qxxs.jpg

You have to remove the 's' in 'https:'

That's awesome! Incidentally, I don't think the link for 'plex' is going to the right place.

Fantastic. As a father of two daughters (7 and 4) I hope mine get as engaged.

I also want to find out more about that CNC they built. Considering it's all scratch built it's pretty amazing!

Amazing work, Dad. A very happy father's day to you, Sir!

This is so wonderful to see! At an age where, statistically, girls lose interest in math and science, Camille and Genevieve are an inspiration. And huge kudos to Robert, for seeing an interest, and fostering it. Keep up the great work, Beatty Robotics!