This Friday we have a brand new soldering kit for beginners that teaches you how to make a flashlight, just in time for Halloween! We also have the new Soft Circuits Kit from ChickTech that covers the basics of e-textiles and wearables, an updated version of the OpenMV, two antennas for your GPS/GNSS devices, and additional parts for your Shapeoko and Nomad CNC mills!

As a reminder, One Day Only Sales are back for the month of October, so we'll be having flash sales on a wide selection of breakout boards every weekday from now until October 26th. Just check the featured content at the top of the homepage each weekday for the new deal! In addition to our breakout board flash sales, we’ll also be taking 15 percent off most of our Qwiic boards through October 31st. Unfortunately, SparkX items aren’t included, but those are a great deal if you’re looking to be on the cutting edge of SparkFun’s product development.

Learn the Basics of Soldering and Circuits!

Are you new to soldering? This Flashlight Soldering Kit is an easy-to-assemble soldering kit designed to help teach the basics of through-hole soldering and circuit design. This kit only requires you to solder four unique parts onto a PCB and insert a CR2032 battery. Once completed, you will have a simple flashlight that will light up dark areas and keep the monsters away!

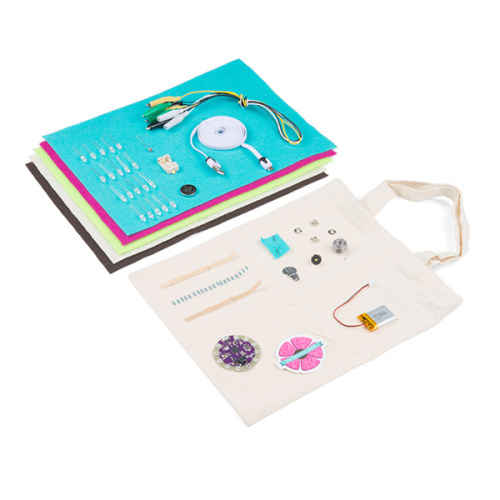

ChickTech's Soft Circuits Kit is a fun combination of electronics, software and art! Using the materials in the kit, you'll learn the basics of electronic circuits and coding with Arduino by creating a LED bracelet and a unique and interactive totebag - no prior experience necessary! To design your own soft circuits, you'll learn to sew so that electricity flows, code with the LilyPad Arduino and create plenty of exciting projects!

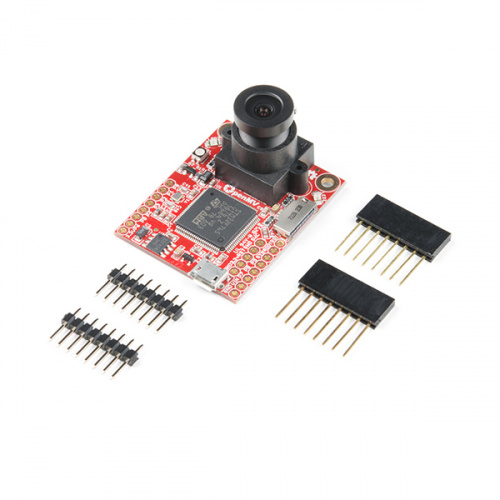

The OpenMV M7 Camera is a small, low-power microcontroller board that allows you to easily implement applications using machine vision in the real world. The best part about the OpenMV is that it is not only capable of image capture, but also face detection, color tracking, QR code reading and plenty more. If you are looking for an economical camera module boasting multiple high-end features, look no further than the OpenMV M7!

Today we also have two new antennas for your GPS and GNSS devices! One is a Magnetic Mount Antenna and the other is an Embedded Antenna. Make sure to check them both out!

To help with all your CNC needs we also have five brand new accessories, including two new drills, collets and an edge finder! Make sure to look through them all and see if there is anything you might need!

That's it for this week, folks! As always, we can't wait to see what you make! Shoot us a tweet @sparkfun, or let us know on Instagram or Facebook. We’d love to see what projects you’ve made!

We'll be back next week with even more fantastic new products!

Frist it’s a great video, we also think it very useful But i have a suggestion. For me i comeform Pakistan,this things are expensive. If i want make it i will pay more, in the other side i fonud another ways to do this. When i surfing at the Youtube,I find a New PCB company this (https://www.pcbgogo.com?code=y) He offers me some good PCBs i can fix them, Maybe u thinks this is a spam but all things is true, Thanks for reading it's useful to poor people.

Hey 651, Glad you enjoyed the video! Definitely not spam to mention other PCB fabrication options. It's truly amazing how many great deals are out there these days. SparkX is constantly on the search for cheap deals for our quick turn prototyping options. I think I hear about a new fab house from them every month. I don't believe we have tried PCBgogo yet, but I'll pass on the word. Our usual prototype PCBs come from OSHpark or PCBway.

If you are able to use the design files from our GitHub repo page to order your own PCBs (and find the parts necessary), by all means, please do! That's the true open source way! It especially makes sense if you were planning on making a large amount of kits. We hope that our kit can be a convenient and affordable option for most, but if you're willing to do the research and bulk ordering, then go for it! We'd love to see your finished assembly. Please post a picture. Thanks for your comment and good luck!

Although it's a great video, I do have a couple of comments:

First, you don't have to have all that fancy equipment. A much more minimalist approach might be good for getting folks who are "on their own" and just getting started interested. While the mat is nice, it's not critical, and a "cheap-o" non-temperature-controlled soldering iron is a LOT easier on the budget than that fancy Weller. I'm glad you stressed safety glasses. I would add that for a beginner, although just about any wire cutters will do for this project, if you're going to buy new ones, look for ones marked "flush cutting". And, as you said, tweezers are not important for this project, though are handy for some others. (It's also good to mention that you need a rosin core solder, and NOT an acid core solder! If you go down to the hardware store, you'll usually find both types available.)

Wow! Soldering at just 3 years old! I thought I was doing good starting at about 12 years old! That was over 50 years ago, and I started out using a soldering gun!

Oh, one other thing: It's always a good habit to be in to go wash your hands thoroughly after doing ANY soldering. Even though you're using lead-free solder, it still has some nasty components, and you want to get any traces off your hands before eating or drinking. (For more advanced folks, I recommend reading what the lead-free solder is made of, and if it contains antimony, don't buy it. The very name "antimony" comes from the fact that it poisoned the monk that discovered it.)

Hey 773, I definitely agree. The Weller WE1010 we used in the studio, the high-precision flush cutters and the matte are on the nicer side and cost a bit more than what's necessary for a total newbie. We have a beginners tool kit that is a good option, or if you want to go super minimalist, just this iron and solder would get ya there.

Also, good advice about the rosin core. We always just order up some more internally here at SparkFun, so I had forgotten about what other options are out there. I just looked at our solder and the ingredients read as follows:

96% Sn (tin) 3% Ag (silver) 0.5% Cu (copper) 0.15% Sb (antimony) Eek! How dangerous is this? I'm wondering if we should look into our supplier and see if they can omit that.

With this in mind, thanks for the reminder about washing hands. Definitely a good idea. As always, we appreciate you comments. Thanks!

I wouldn't worry too much about 0.15% Sb (if it were 5%, then I'd be worried), at least not for electronics. Avoiding breating the smoke, and washing hands before handling food/drink is probably sufficient. I'm more adamant about avoiding Sb in plumbing solders, as then there's the possibility of leaching into the water or reacting with stuff in the water.

Thanks for your advice on this 773. I'm glad to hear, in your opinion, we should be safe at 0.15% Sb.

I'm sure you've already read about this, but for those who haven't I found the wiki page on Sb applications quite fascinating. Fun to learn what else this element is used on, and it looks like we're gonna run out in just 13 years!

A couple points about the video.

Water soluble flux core solder: Ok, the water soluble flux is easier to clean because water will clean the residue off. But, you MUST clean the flux residue where regular RMA flux is only a should clean the flux off. This is because the water soluble flux is much more hygroscopic than RMA or RA fluxes. So, under normal humidity conditions water soluble flux residue will actively promote corroding the board...

710°(I'm guessing F here... you don't specify) is still pretty hot for regular solder. I usually use 650°F which might still be a bit on the hot side... Is the solder you are using lead-free? That might explain the need for 710°F... Ok... I just got to the point where you are soldering, and I can see from the way the surface finish goes matte when it cools, you are using lead-free solder.

While I generally like the SparkFun large models (I really like the large iron tip with the explanation of what part of the tip to use), I don't like the large chocolate kiss example for a good soldering joint. If a soldering joint looks like that I would worry about poor whetting to the solder pad because the bottom comes in towards the center.

Otherwise good video.

Hey Sembazuru, Good points for sure!

If you don't plan on cleaning with water (or can't), then maybe a "no-clean" solder would be a better option. We clean everything here at sparkfun, either in the big production batch washer or (if there's rework), then with a brush and croc-pot. Having compressed air also helps get all of the water (and flux) off the board completely. I suppose we are also lucky that Colorado is such a dry climate.

Sorry about that. The setting was already on F, so I was just reading it off the display. 710 F = 376 C. I should have mention both. And my parents are Welsh too :)

Another good point. The bottom of the chocolate kiss model does indicate a poor connection at the bottom. Small regular chocolate kisses have a much better solder joint that taper down nicely to the outer edge of the annular ring. For what it's worth, in the hookup guide, M-SHORT references a nice graphic with some good/bad solder joints. I hope this helps all the first-timers.

Thanks for your input!

Sort of related to my previous comment, but more relevant to Sembazuru's comment: Yesterday I happened to recall an incident back in the 90s when the Sun Microsystem tech told me that at a previous service call she'd found a "daily vitamin" tablet inside the computer that had apparently been there two or three years. Even here in the Phoenix area it had absorbed enough mosture that some of the chemicals in it had corroded all the way through the PCB traces under the tablet! (Makes you wonder if those vitamins are really all that good for you...)

Dang. That's crazy! I'm usually pretty amazed hearing corrosion stories about circuit boards. I wonder if space is any easier?

I once attended a manufacturing conference put on by Aqueous Tech (the manufacturer of our batch washer), and they got me scared of shipping out product with even just plain old dust :) 99% of our products go through the washer. It's those darn "no-clean assemblies" that keep me up at night! But some of our products just can't get wet (most of our weather products that have humidity sensors, and the new GPS-RTK). On these assemblies, we have to use a no-clean solder paste, which most of us around here think looks pretty darn ugly.

Also, this reminds me of an interesting project that involved some difficult corrosion problems to solve. We were lucky enough to have Damon McMillan come talk to SparkFun about his sea charger.