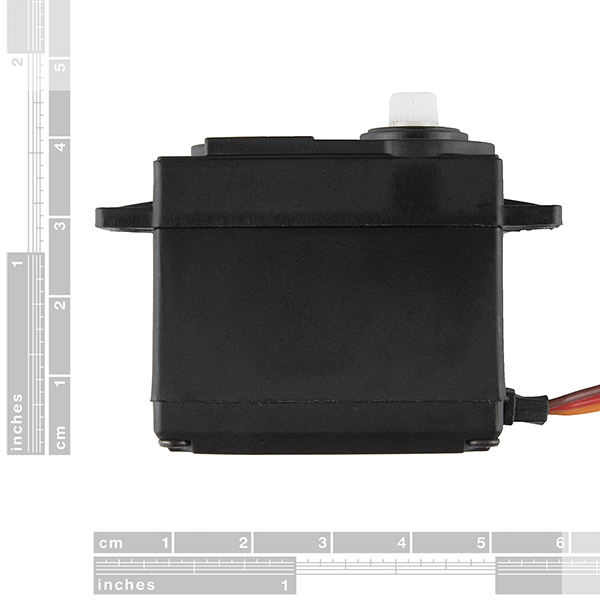

Servo - Generic High Torque (Standard Size)

Here is a powerful, low-cost, reliable servo for all your mechatronic needs. This servo is able to take in 6 volts and deliver 83.47 oz-in. of maximum torque at 0.16 sec/60°

This is a tough little servo with a standard 3 pin power and control cable, and all hardware listed below.

Replaces:ROB-9064

- 1x FS5106B High Torque Servo

- 1x Double Arm Horn

- 1x Circle Horn

- 1x Four Point Horn

- 1x Six Point Horn

- 2x 3x10mm Phillips Screw

- 4x 2x13mm Mounting Phillips Screw

- 4x Rubber Grommets

- 4x Brass Eyelets

- Voltage: 4.8-6.0 Volts

- Torque: 69.56/83.47 oz-in. (4.8/6.0V)

- Speed: 0.18/0.16 sec/60° (4.8/6.0V)

- Direction: Counterclockwise 1000-2000usec

- Rotation: 180°

- Dual Ball Bearing

- Nylon Gears

- 25T Spline (Futaba 3F)* 40.8 x 20.1 x 38mm

- Wire Length: 300mm

- Weight: 40g

Servo - Generic High Torque (Standard Size) Product Help and Resources

Servo Trigger Hookup Guide

March 26, 2015

How to use the SparkFun Servo Trigger to control a vast array of Servo Motors, without any programming!

Hobby Servo Tutorial

May 26, 2016

Servos are motors that allow you to accurately control the rotation of the output shaft, opening up all kinds of possibilities for robotics and other projects.

Basic Servo Control for Beginners

February 25, 2020

An introductory tutorial demonstrating several ways to use and interact with servo motors!

Compatible Hubs and Gears

Generic servo that has a 25T spline. You can use the hubs and gears that have a 25T spline like the 3F Standard Futaba Splines https://www.servocity.com/html/futaba_servo_splines.html#.VJNSwHsYF8F.

Here are some examples:

Power Supply

Make sure that you use a separate power supply that is sufficient enough to power the Generic High Torque Servo. 5V from a computer's USB port and Arduino microcontroller will not be sufficient enough to power the system. The servo can pull enough power to brown out your Arduino or not move the servo.

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Competent - You may need an understanding of servo motors and how to drive them. Additionally, you may need some fundamental understanding of motor controllers.

See all skill levels

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.8 out of 5

Based on 5 ratings:

1 of 1 found this helpful:

Solid standard servo

I've used a couple of these. The ball bearing feels like it adds some stability and ruggedness. One motor has been in use for 400 hours of maybe 30% duty cycle at a torque that I have not measured but that is neither particularly light nor terribly heavy, with some software acceleration/deceleration to ease the job. The more generic servos died much sooner in this same job, though that was before I added the software acceleration control so it's not a great comparison.

1 of 1 found this helpful:

Tough excellent servo

Powerful. I am using them imbedded in an arm where they can hold the weight in position with no sweat. Careful though - they do take current when lifting a load. My little power stick could not handle the power drain so I use 4 of them on their own breadboard fed straight from the battery.

1 of 1 found this helpful:

Excellent torque, was able to power without shield

This high torque servo was able to connect to my gripper without incident and was able to hold onto quite a bit of weight, even when it was underpowered at 3.3v.

Would buy again!

1 of 1 found this helpful:

Works well, I want more.

I cannot say that I have used a lot of servos. I needed something better than the cheapest ones. This one is being used to lift a sensitive digital scale under an object to weight it. It is working very reliably and repeatably moving to exactly the same place each time. Like other servos it has a bit of vibration and this is enough to throw off the weighing (my resolution is in .01 grams). Fortunately it has enough resistance to movement that it looks like if I turn off the power the vibration will be gone. I really appreciated the variety of mounting hardware that came with it. I hope to buy a few more as spares.

Real workhorse

I use these for steering front wheel of 3 wheel robot. They just keep working, I have 3 robots with servo steering on all of them.

For those outside of USA the torque is about 50 N*cm.

Hi, I never used servomotors before. What control voltage do they need? Can these be used with a microcontroller which has a 3V power supply?

4.8-6V for power, signal might work on 3V, datasheet doesn't say.

since it's got electronics it's not like a normal motor, not enough volts or amps means it does not operate.

I would like to attach these to a proto-board in a removable way, but I'm afraid they could come lose if I just use a male header. Does anyone know of a connection that would be more secure?

this is the same connector using in RC cars. unless you have something tug on the wires, it's not going to come loose very easily. you could always add some kind of physical latch or restraint.

The servo use good," I have 5 of these motors and they all stall and/or stutter when setting an angle less than 7",the buddy not correctly adjust parameter,i think.

Two questions -

1 - Does anyone know of good pan / tilt brackets for this motor? 2 - How much weight can this motor support?

Would appreciate help and guidance. I'm new to this but very excited about my first project!

These motors seem to function on a 7 degree to 180 degree scale. I have 5 of these motors and they all stall and/or stutter when setting an angle less than 7. Other motors I have running the same code are functioning fine. Whats the problem? (Running Sweep arduino example code no modifications)

Hi you need to modify Servo.h as follow {

define MIN_PULSE_WIDTH 544 // the shortest pulse sent to a servo

define MAX_PULSE_WIDTH 2400 // the longest pulse sent to a servo

define DEFAULT_PULSE_WIDTH 1500 // default pulse width when servo is attached

define REFRESH_INTERVAL 20000 // minumim time to refresh servos in microseconds

} Modified to {

define MIN_PULSE_WIDTH 700 // the shortest pulse sent to a servo

define MAX_PULSE_WIDTH 2300 // the longest pulse sent to a servo

define DEFAULT_PULSE_WIDTH 1500 // default pulse width when servo is attached

define REFRESH_INTERVAL 20000 // minumim time to refresh servos in microseconds

} You can to try it, this servo will work very good.

you don't need to modify at all. just pass the min and max to the attach function.