Micro Gearmotor - 90 RPM (6-12V)

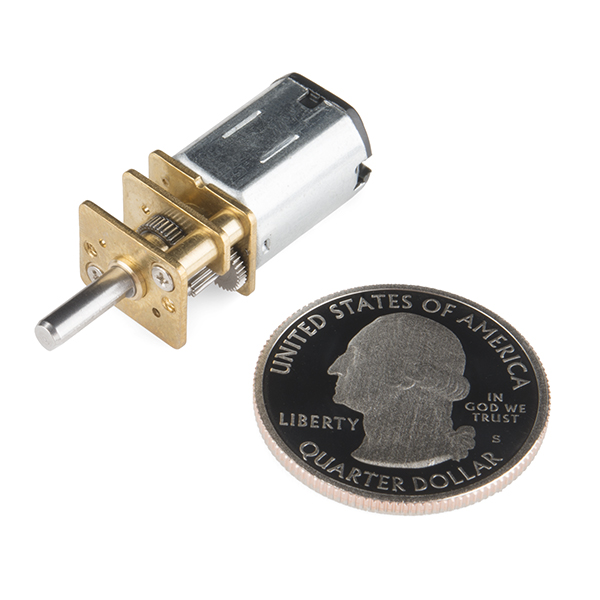

These micro gearmotors are incredibly tough and feature full metal gears. They have a gear ratio of 298:1 and operate up to 12 volts and have a stall torque of 70 oz-in. and a max speed of 90 RPM. Each micro gearmotor sports a 3mm D-shaft.

Note: The micro gearmotor enclosures are sold separately, you can find them here.

- Voltage: 6 - 12 Volts

- Gear Ratio: 298:1

- Stall Torque: 40/70 oz-in. (6/12V)

- Speed: 45/90 RPM (6/12V)

- No Load Current: 30/70 mA (6/12V)

- Stall Current: 360/1600 mA (6/12V)

- DC Reversible* Motor Size: 26 x 12 x 10mm

- Shaft Size: 3mm Diameter x 10mm Length

- Weight: 17g

Micro Gearmotor - 90 RPM (6-12V) Product Help and Resources

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Rookie - You will be required to know some basics about motors, basic motor drivers and how simple robotic motion can be accomplished.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Noob - You don't need to reference a datasheet, but you will need to know basic power requirements.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.3 out of 5

Based on 6 ratings:

1 of 1 found this helpful:

Works just fine

It does exactly what I want it to do

3 of 3 found this helpful:

Works just fine

It does exactly what I want it to do, which would be 5 stars

Very strong

Very good strength for the size.

Very good geared motor

very small in size but strong as an output torque.

Very happy with this gearmotor

This is deceptively small. From the photo, I was assuming that the motor was the size of a standard hobby motor. This thing is tiny and is perfect for my application.

You will need an enclosure of some sort to mount the motor. The mounting holes in the front gear plate are tiny and look like they are about the size of watch batteries. The best mounting method is to capture the assembly in an enclosure. I 3D printed an enclosure for my application.

The torque is awesome for a gearmotor this small. This thing has so much torque that I am actually going to order one of the versions with less reduction for faster manipulation in my application.

Sparkfun - You folks should create a CAD model. IF you would like, I can send you the one that I created.

Link it here :)

What is the dimension of the shaft's flat cutout? (like how much less than the 3mm diameter is cut). I'd like to make a hole of the same shape on my CAD of a part to be 3D printed.

Can I get a data-sheet to the motor. Also does anyone know the type of resistor is needed for this motor.... I would greatly appreciate the response.

Thanks,

-------------------- Tech Support Tips/Troubleshooting/Common Issues --------------------

Extending the Shaft of the Microgear Motor

If you are looking for a way to extend the microgear motor's shaft to add an encoder, feel free to use the Shaft Coupler - 1/4" to 3mm [ https://www.sparkfun.com/products/12412 ]. You would just need to find a shaft length that is suitable for your project. Here's an example from ServoCity using a shaft coupler with a micro gearmotor => [ https://www.servocity.com/media/catalog/product/cache/1/image/438x280/602f0fa2c1f0d1ba5e241f914e856ff9/c/o/coupler_on_gearmotor_with_shafting.jpg ].

Are the holes in the brass plate tapped? If so, what size?

M1.6x.35

Any tips on how to solder wires onto the little tabs? Or better, how to make a secure connection without soldering?

Are these motors supposed to come with 6" long wires (listed under Dimensions)? Because my motors didn't come with wires...

Can I get a datasheet?

you should set the the preview picture to the second one with the quarter...