Dplomat

Member Since: February 16, 2011

Country: France

-

What got me into electronics when i was a kid was this kit: http://radioman64.e-monsite.com/pages/les-boites-de-jeu-radio/laffont-electronique-detection-et-alarme.html

Like other kits using those truncated-cone shaped springs, but instead of holes here and there, there was a clever high-density of holes under that you can use to build more complex circuits, but you can cover them with schema sheets for easier initiation on the predefined circuits.

Then at middle school we used wooden boxes with discrete components and banana plugs, which i found rather bulky and spaghetti-wiring prone. Built some of those for my home use, but came back to the former kit until i ran out of those neat springs, then using paired screw terminals (unreliable with thin wires of typical signal components), then learned to solder and went the 'solder leads on tacks on wooden plank' route, until some years later moving to breadboard, stripboard and PCB-etching.

I wonder if those springs can be sourced easily nowadays, as the rest of the kit build keeps relatively low-tech and common parts, only drilled panel and schema-sheet masks, and also keeps compatible with alligator clips.

-

Done, i let you check my other post... happy PoE hacking :)

-

Well, i've finally completed the torture-test of this part for current-handling capacity, and it reveals itself very capable for its size. Results with arbitrary safe derating, before the TLDR details: 400mA continuous, up to 600mA vith thermal plane and/or some aiflow, peaks to ~1A for some seconds if it has time to cool down between, dies after 40min at 1.5A in open air.

The test setup:

A passive PoE injector powered by a 12V 6A power brick, a 20cm Cat5 patch cord to rule out cable losses, short wires soldered to the magjack power pins, green LED + 1kΩ resistor, and load resistors from KIT-13053, used in this order: 2 x 16Ω in series for 32Ω load, 2 x 8Ω series for 16Ω, 3 x 4Ω for 12Ω, 4 x 2Ω for 8Ω, 3 x 2Ω for 6Ω

Some caveats to keep in mind:

- room temperature was about 19°C, and the magjack placed in free air on a ceramic tablemat, so a very optimistic setup for heat dissipation by natural air convection, probably the same test in a plastic enclosure in a 25°C room would have failed much sooner.

- test was done with one part only, should sacrifice a second one to see if any variance

first measure voltage at jack output without load: 11V => 1V fV drop for the diode bridge unloaded

Then the actual tests, plugging the load resistors with:

- VR = measured voltage at load resistors

- I = measured current

- PR = calculated total load resistors power (VR x I)

- VD = calculated diode bridge forward drop (12 - VR)

- PD = calculated power dissipated by the diode bridge (VD x I)

Don't have an IR thermometer so just a vague appreciation of how hot it feels.

32Ω load:

VR=10.75V, I=315mA => PR=3.4W, VD=1.25V => PD=0.4W 1h30 later: magjack barely warm16Ω load:

VR=10.54V, I=650mA => PR=6.8W, VD=1.48V => PD=0.95W 2h later: magjack hot12Ω load:

VR=10.48V, I=850mA => PR=9W, VD=1.52V => PD=1.3W 12h later, overnight: magjack very hot, can't touch it more than 2 second8Ω load:

VR=10.25V, I=1.23A => PR=12.6W, VD=1.75V => PD=2.1W 1h later: magjack immediately painful to the touch6Ω load:

VR=10.1V, I=1.56A => PR=15.8W, VD=1.9V => PD=3W 15m later: very faint but typical smell of electronics suffering overheat 40m later: magic smoke leaves out the terrestrial body of the mighty magjack, LED goes offThen, putting the Am-meter right between the power brick and the PoE injector shows no current (10mA, LED on the injector), so the diode bridge has failed open gracefully rather than short-circuit. Good news for people using dumb/passive PoE without current limiter (aka Fire over Ethernet protocol), though i would never rely solely on this over a proper current limiter or fuse.

Also, seems like part of plastic of the RJ45 connector of the cable melted inside the jack, as i can't anymore unplug it. Something to watch out, as you can't rely on simply unplugging (this end of) the cable as an emergency cut-off. (Even while still hot, pulling a melted still powered connector could likely cause a short, so always keep the other end of the cable, or better the power supply itself at reach for safety)

An interesting feature is the way the jack case heats, appears this part is doing a great job of using its metal case for dissipating heat away off the diode bridges.

To sum-up, i'd say it can safely be used up to the maximum of 802.3at PoE+ (Type 2) spec: 600mA on one pair of Cat5 cable, though above 350-400mA i'd recommend a PCB thermal plane and/or some airflow around the jack.

With a PoE+ voltage of 42 to 57V at powered device, depending on cable length and quality that still allows for a 25 to 34W load minus the switching reg losses.

Way more than enough for powering even a RasPi with loads of peripherals, and absolutely no thermal concern for my current uses: Omega2+ PoE dock and ATmega328+ENC28J60+HTU21D sensors PoE powered boards.

For those thinking of PoE type 3 and 4 (1.2 and 1.9A!), which uses all pairs for power, well, according to the datasheet there are actually two diode bridges inside, so the current would be spread across the two, but the failure timing and symptoms (after 40min continuous load) is clearly a case of thermal buildup rather than instant current overload, so that wouldn't help much more.

I doubt such current handling bridge could reasonably be implemented in something this compact and integrated (maybe using schottkys instead of PNs to reduce fV drop and thus dissipation?), all i've seen requiring this much power use external diode bridges (as those are obviously no more thumb-sized MCU+sensor boards)

But still very neat for miniaturization of low-power circuits and even powering very capable SBCs like RasPi.

-

Maybe they had the wrong datasheet or part number and they've corrected between, but their current datasheet at: http://www.hqelec.com.cn/spec/hanrun/HY931147C.pdf is the same i had and clearly says "for 10/100Base-TX PoE application"

-

In fact you can use whatever for the second to last byte, but there are some restrictions on the first byte: the two lower bits are flags for global(vendor ID)/local(arbitrary) and unicast/multicast.

The second digit should be even to have an unicast address (bit0 = 0) Otherwise it will sometimes work on a direct link PC <-> Arduino but not with some ethernet switches between.

Also to be more standards compliant i set bit1 = 1 for local address. This one is not critical, it would just prevent the very unlikely conflicting with an actual device, and also avoid some network scanner/mapping tools to identify your Arduino as an HP/Cisco/3Com device or whatever the vendor-id part of the MAC would happen to belong to.

To sum-up the first byte should end by 2, 6, A or E. (used 0xDE in my case)

Here is the detailed explanation i've had on actual testing: http://www.incrediblediy.com/2013/03/arduino-based-webserver-atmega328.html?showComment=1483930305539#c4443782262393030090

-

Zooming on the picture on the page of the PoE shield, we can read HanRun HY931147C on the magjack. Supposing it's the actual part, i've found a datasheet here: http://www.knap.at/datenblaetter/ste/ste_han_hy931147c.pdf

I'd be interested in buying some dozens if you could confirm it's really this part. Also searching for other PoE magjack models it appears there are some other with compatible pinout, sounds good news, as i'd like to have a reliable not too hard sourcing of parts for a current design i'll be extending and integrating into larger products.

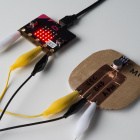

-- UPDATE 2017-05-20: I've received 12 of those i've ordered, like in the picture on this page no marking on case, but i'm pretty confident they're actually HY931147C: Testing them with multimeter shows R(p2.p1)~=R(p2.p3)+R(p3.p1), same for p6.p4.p5, and a diode test on p9 and p10 shows no current one way, and 1.2V forward drop the other so it seems they also have the integrated diode bridges. Saving PCB estate of 2 DA4X106U0R or MB1S and associated traces :)

The datasheet doesn't mention max current for those diode bridges, so i'll sacrifice one for a max prolonged-load testing when i've returned to my lab and etched some breakouts (For those using KiCAD there is a footprint for this part in freetronics_kicad_library)

-- UPDATE 2017-05-22: Well, made 6 breakouts for those, and testing with some passive PoE injector i have the voltage present on P9 and P10, except the polarity is reversed compared to the HY931147C datasheet, i have + on P10 (outermost) pin and - on P9. To confirm the diode bridge is working well, i built a PoE injector with reversed polarity from an old RJ45 wall socket, at least the diode bridges are ok, as i still have +P10 and -P9. So either there's an error on the datasheet, or we have the nasty situation of 2 existing parts, one with no marking with exact same footprint but reversed polarity... will try to get somewhere one with the marking HY931147C to check if it's an error on the datasheet or really two different parts.

-- UPDATE 2017-11-03: Received a part marked HY931147C from another source, and confirms it has reversed polarity. Thought of adding a diode bridge but loses both neat integration and efficiency, so i'll keep using this one for my designs, and switch polarity on my future boards when this one no more in stock.

-

I've got some of those i bought about 15 years ago at a local dealer, both N/O and N/C versions.

The one on RS picture looks like my N/O versions (plastic inner cylinder of pushbutton) while Sparkfun's one looks like my N/C (metal inner cylinder)

At the time i preferred the N/C that are very sensitive while the N/O needs to have the button pushed on its full course to be on.

I had those stored in unoptimal conditions (humidity), and while the N/O degraded (needs some force to close the circuit and huge contact resistance varying with push-force), i was surprised to find the N/C kept all their binary and responsive touch, maybe N/C contact are somewhat more moisture-resistant.

-

I suppose the way to go from Arduino would be:

-use Ardupilot code

-convert to plain C++ AVR code with Makefiles etc

-generalize a bit the hardware handling code "drivers" for gyro/accel/compass (maybe an intermediate step would be Ardupilot ported to Arduino + 9DOF IMU, I'm in the process of doing this as i've got one but have very few spare time...)

-port the code to LPC2148 MCU

About the servos, either you must use digital servos conneted to I²C but that would mean much wiring in I²C, not toot good for using the bus with fast sensors, an I²C IO expander or soldering wires to GPIO pins and implement PWM.

If one day I manage to have 9DOF IMU + Ardupilot working well I might upgrade to this awesome unit as the HW specs of the ATmega (2k SRAM!!) is the next obvious limiting factor -

looks like space-wise the Li-Ion is better, but when weight matters LiPo is better

-

Maybe a bit overkill for this use, but it can power a chinese bluetooth mouse for two full days of intensive use:

review and upgrade of 6D rechargeable bluetooth mouse

No public wish lists :(