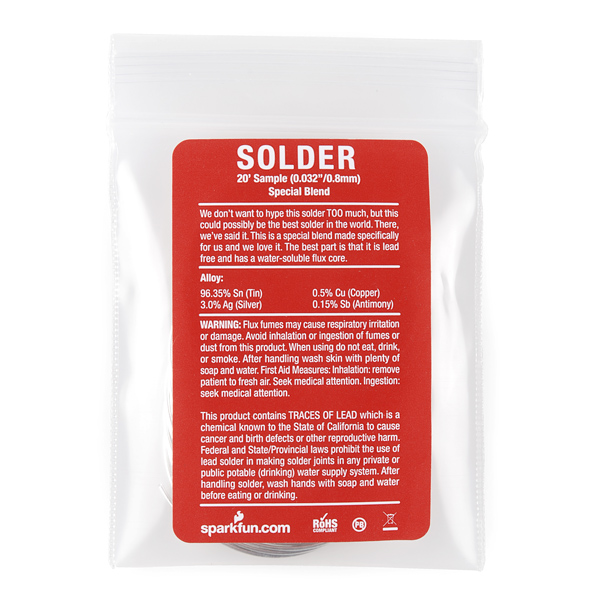

Solder - 20' Sample (0.032") Special Blend

We don't want to hype this solder TOO much, but this could possibly be the best solder in the world. There, we've said it. This is a special blend made specifically for us and we love it. It all started as a quest to find the best solder to use in our production process and ended up being the best we've tried. The best part is that it's lead free and has a water-soluble flux core.

This package contains 20 feet of solder and has a diameter of 0.032" (0.8mm).

**Mix: **96.35% Sn (Tin), 3.0% Ag (Silver), 0.5% Cu (Copper), 0.15% Sb (Antimony).

- [MSDS](http://cdn.sparkfun.com/datasheets/Tools/MSDS Indalloy with Fluxcake-301 (CW-301).pdf)

Solder - 20' Sample (0.032") Special Blend Product Help and Resources

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Noob - Some basic soldering is required, but it is limited to a just a few pins, basic through-hole soldering, and couple (if any) polarized components. A basic soldering iron is all you should need.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3 out of 5

Based on 1 ratings:

Solder seems to work well, but be careful with the flux

I ordered this thinking, "Hmm, Sparkfun seems to recommend this stuff for lead-free soldering, why don't I give it a try?". It was great of them to offer a sample while it lasted, because then people could give this solder a try for a lower price rather than buy the entire spool for $25. At the time I didn't have that kind of money.

Compared to the other lead-free Sparkfun solder (Sn99e alloy), it was OK. The solder itself seemed to flow well and leave shinier joints than regular SAC305, but I tended to get charred black bits on the iron tip. I later learned that this is the burned flux. As I didn't have the luxury of working in ventilated areas, I got to experience the smell of the flux vapor, and while it's not the most pleasant thing in the world, it smelled better than the Sn99e solder and cigarette smoke. The one annoying thing I found about it was that it was covered in a sticky residue (as I later ascertained, the flux). It was like working with solder and sugar syrup at the same time for some reason.

Fast forward a few years and now that I've learned more about soldering and fluxes, I feel that I should inform people to be careful with this stuff and all water-soluble fluxes in general. While it's convenient to have a flux that you can simply clean off with warm/hot water (and an electronics-safe soap if you've got it), water-soluble fluxes are organic, and they tend to be quite aggressive. Looking at Indium's information on the flux used in this solder (CW-301), its IPC rating is ORH1. Translated, that means, "Organic, high activity, some halides." High activity means that you can use this on brass/copper/tin surfaces that aren't perfectly clean or in circuits where some of the pads are a bit corroded, but this is by no means a "no-clean" flux-- you have to clean this stuff up in a production environment, or you will be very sorry you didn't. Additionally, in situations where the surfaces of your components/boards are already clean to begin with, this is probably overkill and can even eat into copper traces if left on the board. In practice, I don't recall running into a trace failure or such because I didn't clean it off, but because of the aggressive nature of water-soluble fluxes, I would rather be safe than sorry. The presence of halides makes me a bit wary of using this without proper ventilation or filtering of the flux vapors, though to be honest, I don't recall my throat drying out after using this stuff.

It would be cool if Indium/Sparkfun offered this with an RMA flux (CW-802 or CW-807) that isn't as aggressive (doesn't have to be no-clean, I personally like to clean off the board because most fluxes are sticky afterward), or just the alloy itself, since the added antimony appears to improve the appearance of the joints and improve visual inspections. Whatever flux can be added beforehand (I'm liking the Amtech series personally), and as long as the surfaces aren't too corroded, most good fluxes can clean them for most solders.

Feel real inadequate to not know the ideal chemistry of solder.

made in usa, i like it :)

Does the flux have to be washed off a board like the old Kester organic flux solder (which corrodes if you don't wash it)? Or can you use it for everything, washable and non-washable parts alike?

Somebody commented on the .020" sample that you should clean it with a wet Q-Tip or similar because it is corrosive.

0.032" = 0.8mm not 0.5mm as noted in the description. Cut and paste error I think

I had trouble using the leaded solder with my butane torch and found out I should be using flux with that. Since SparkFun can't sell flux right now, I got this solder and it works perfectly.

As a novice, finding something that just works is awesome.

What am I doing wrong with this solder? I used it to solder a header onto a breakout board. The solder did not flow well, and it seemed to frost a lot. I have no problems with the 63/37 mix.

63/37 is a leaded solder - this is not.. you'll want a higher temperature. 380°C worked well for me with the sample I got.

My iron has nothing to tell me the temperature, neither does it have a precise control. Maybe someday I can get a better station. Thanks.

Is it just me, or does this solder smell sweet when it burns? LOL, I'm trying my best to avoid its burning vapor, but DAMN it smells weird!

BTW, for those who never tried this, this REALLY is the greatest solder ever (AFAIK). Somehow, it perfectly flows unto the holes and rarely sticks on your soldering iron (this is great for an utter klutz like me who shakes like insane and can't solder for sh**)

I just wish it wasn't that expensive! Damn you, silver! Y u so expensive?! :P

oh, btw, get the thinner one (.02") if you tend to oversolder things (blob wars) like me...

I feel Like I must ask, What differentiates this solder from regular solder? What, in the opinion of Spark-fun, makes this superior? I suppose I may be a solder Philistine because up until I read the description of this item I assumed one solder was just as good as another solder.

By my calculations, the mass of this 20-foot sample is about 23.6g. This is taking the densities of the primary constituents, tin and silver, to be about 7365 kg/m^3 and 10490kg/m^3 respectively. By comparison, the 1/4lb mini-spool of this blend is about 131.5g of solder and the 1lb spool accounts for 454g. You can compute the value-for-money quotients on your own.

Conclusion: If you're thinking about buying this solder blend, pick up the 1/4lb mini-spool instead, as it's 5x better value (as of this writing.)

I hope Rob included some of THIS in my prize pack...

Surprisingly, the only good and cheap solder (2% Ag) that I could find was at the local Radio Shack.

Will you sell thinner solder in the near future? (the Shack version is 0.015")

What's the melting point of this solder?

Antimony... who'da thunk it?

I'll take a roll, let's see what this stuff can do...

Hmm pretty toxic. I gonna buy some!!!

This flows better than most leadless solder.