uArm Swift Pro

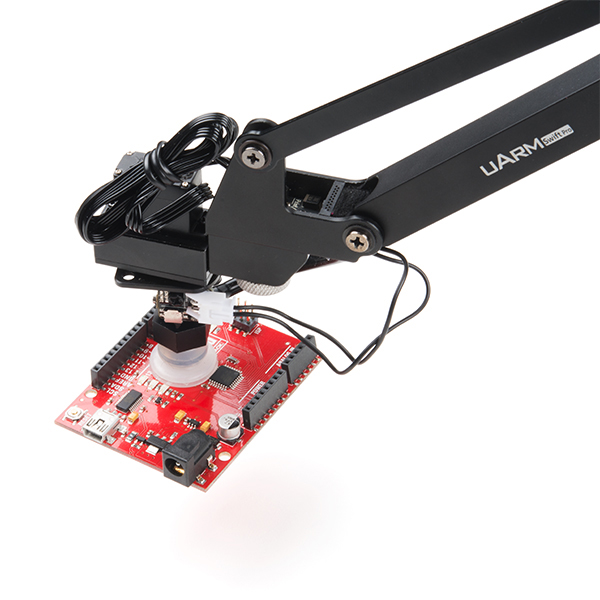

The uArm Swift Pro is a high grade desktop robotic assistant that can be utilized in many more applications than its predecessors. Built around an Arduino Mega 2560, the uArm Swift Pro is an open-source and DIY friendly robotic arm platform developed for makers and educational purposes. This little bot is extremely easy to use, almost anyone can learn how to play with it in a few minutes. The uArm supports visual programming as well as Arduino, Python, GRABCAD and ROS programming providing plenty of options for any range of user. Unleash the maker inside and get uArm to make your idea happen!

The uArm Swift Pro has a repeatability of 0.2mm with a maximum payload of 500g making it one of the most high tuned consumer grade robotic platforms on the market. Thanks to its high quality stepper motors, four degrees of freedom, and its advanced controlling algorithm, the uArm Swift Pro performs not only with accuracy but also with smoothness and stability. Thanks to these attributes, the uArm Swift Pro can even be used in laser engraving and 3D printing situations with appropriate end-effectors.

Each uArm has several ways of operation and control. The easiest way to start is with Offline learning mode which requires no coding experience or complicated assembling at all. You simply need to power it on, press record, teach the arm what to do by dragging it and that's all! uFactory has also developed two intuitive apps to control the uArm. uArmStudio, comes in a clean and intuitive user interface with instructions, setting and diagnosis built in for Windows, Mac OS, and Linux while uArm Play is available for smart phones.

- 1x uArm Swift Pro

- 1x Power Adapter & Cable

- 1x 4th Axis End-Effector Adapter

- 1x Suction Cup End-Effector

- 1x Base Extension Board

- 1x Seeed Grove Extension Board

- 1x USB Cable

- 1x Screw & Tool Set

- Arduino Mega 2560 Motherboard

- Customized Gearbox & Stepper Motors

- 12bit Encoder Position Feedback

- 4 Degrees of Freedom

- Max Payload: 500g

- Repeatability: 0.2mm

- Working Range: 50mm - 320mm

- Max Speed: 100mm/s

- Input Voltage: 12VDC

- Bluetooth 4.0

uArm Swift Pro Product Help and Resources

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Rookie - You will be required to know some basics about motors, basic motor drivers and how simple robotic motion can be accomplished.

See all skill levels

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Noob - You don't need to reference a datasheet, but you will need to know basic power requirements.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3 out of 5

Based on 2 ratings:

4 of 4 found this helpful:

Mechanically OK but poor documentation and hard to interface

I've spent quite a bit of time trying to interface this to a production machine as a pick-and-place part feeder. I was attracted by the 0.2 mm accuracy claim and relatively low cost.

The uArm Studio software like Blockly is cute but gives no opportunity for I/O to other systems, so I ended up writing a C# program to feed the uArm a G-code string through USB and coordinate handshaking with another computer through digital ports. There is no ability to control speed of wrist motion with this approach (or any other that I know of). The G code command set is limited, and documentation is sketchy overall. There are vision interfaces, sensors, etc that I haven't tried. Mainly because of software limitations, this unit tries to demonstrate everything, but seems to do nothing well.

I think I'll get this to do some very simple useful things, but next time I'm going to spend a little more and get a real robot arm.

1 of 1 found this helpful:

Okay As A Learning Tool or Good For Hobbist

We never really expected to put this into any sort of industrial environment. It is a learning and evaluation tool in our eyes.

It can be made to do tasks but it has limitations. For example, the .2mm repeatability claim isn't accurate over a long period. The unit tends to drift if moved over a long distance and at other times just locks up at the end of long mover. Also, commands are sometimes ignored. For example turn the actuator command isn't always performed.

If the support team has fixes or suggestions, please let us know.

ouch! wouldn't bother touching it ... not at that price tag. same design as servo based bots you must be kidding selling this here. the entire bot can be built from parts under $100 sooo no thank you.

If you get to see it, you'll find the design is not the same as the servo version technically. It's much stable and strong for people to finish their own project especially for the ones who want to do some project that needs accuracy, for example, 3D printing, Laser Engraving etc. Its repeatability is 0.2mm, which most of the part-servo-assembly version robot arm cannot achieve. Our goal is to make the robot arm easy and affordable for everyone, so we will try our best to achieve it. Thank you.

I own one of these Swift Pro's. I got in on the kickstarter. I have had it for about 2 months now. It sort of surprises me that SparkFun would offer this product at this time. The reason being is that it simply is not ready for prime time. The software is very buggy, Many things just aren't implemented yet. Documentation is simply not there. I have been working with uFactory people to resolve many of the issues I had immediately run into. We were able to get some resolved, but others are still in the process of being fixed. Two words come to mind here, "Buyer Beware". This is not a full working robotic arm and is not able to perform some functions described in the marketing data. I knew this from the start and bought one anyway. I like my uArm Swift Pro. However, you shouldn't expect to get what they say you will be getting. It's probably best to wait for a while until the software settles down. Mechanically, it's solid. Which is why I choose this particular arm to get. The company is for real and trying feverishly to fix everything. There's just way to much they need to do to get everything working as stated. I will recommend this product for anyone getting into robotics, just be ready to do lots of downloading, searching, updating and communicating with the uFactory people.

Thanks for your feedback. We are currently working extremely hard to improve the software. Each week we get new and valuable feedback and suggestions from our customers, and we take into account every piece of advice. We are very excited to see our community grows bigger and bigger. We've been keeping updating the documentations and the software. The instructions are much more well documented than the earlier, which you can find at our download center. Our goal is to make this robot arm easy and affordable for everyone, so we will never stop effort to make it better. If you have any further questions or suggestions, please always feel free to let us know. Thank you!

Update to failed wrist servo:

I finally received the replacement for the defective (since mid-November 2017) servo, and it did work properly. This was an example of very poor quality control of an expensive (for educational use) training/demo tool. In addition, this is a non-returnable item, according to the SparkFun warranty info listed for this, which is now a "red-flag/non-purchase" to any other school systems that I work with.

Very disappointing purchase as I am still waiting on replacement wrist servo, which was bad from Day 1 (back in November 2017). The "lead-through" programming playback movements are jerky at best, and tend to overshoot the intended path points. As others have said, buyer beware; I should have paid more attention to the comments. This will be a first and last purchase.