Innovating in Quality Control

How is SparkFun staying on top of our quality control game?

Here at SparkFun, we have long prided ourselves on implementing uncommon solutions to common problems. Our hotplate reflow skillet method is one (in)famous example. Another is our pogo bed test jigs that we use to test every one of our designs.

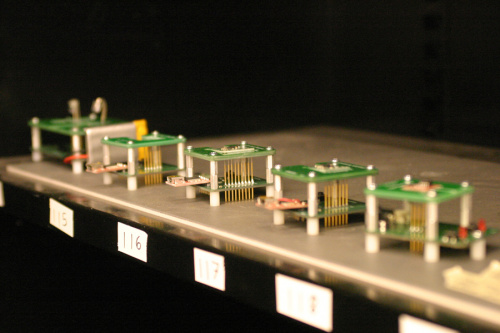

An array of pogo test jigs.

Which brings us to today's post - how does SparkFun work to ensure quality control on our unique designs? Well - in this tutorial from QC Guru Pete Lewis, you'll learn how SparkFun is constantly trying to innovate to keep the performance of our designs at peak levels. Check it out! What else could we be doing differently? What do you think is a great idea? Let us know in the comments section below!