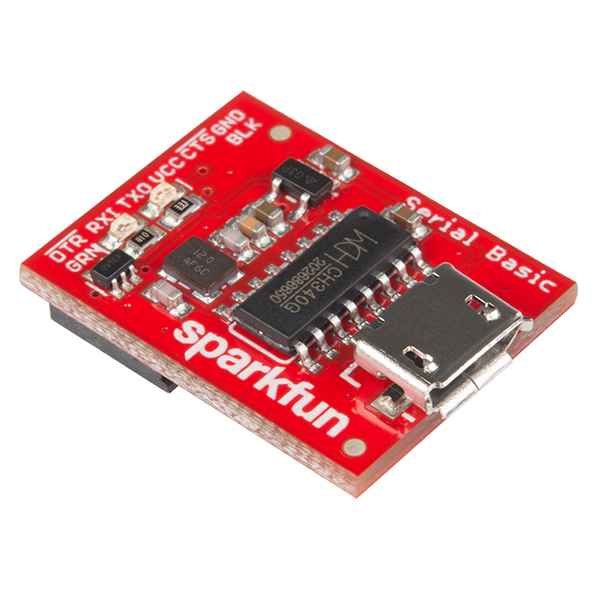

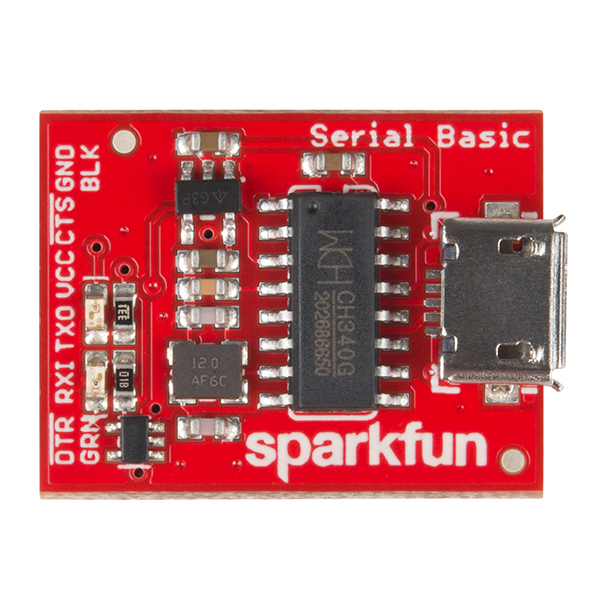

SparkFun Serial Basic Breakout - CH340G

The SparkFun Serial Basic Breakout is an easy-to-use USB-to-Serial adapter based on the CH340G IC from WCH. It works with 5V and 3.3V systems and should auto install on most operating systems without the need for additional drivers. The Serial Basic uses the CH340G IC to quickly and easily convert serial signals to USB. It’s a great lower-cost alternative to the extremely popular FTDI Basic.

The pinout of the Serial Basic mimics the common DTR/RX/TX/VCC/CTS/GND pinout found on hundreds of FTDI-to-USB derivatives. It can also be used as a general serial device for debugging (such as with a GPS module). There is a jumper on the rear of the board that controls the output voltage on the VCC pin. By default, the board outputs 3.3V and has 3.3V signals. Changing this jumper to 5V will cause the board to output 5V on the VCC pin with 5V signals.

- Schematic

- Eagle Files

- Hookup Guide

- Fritzing Part

- Datasheet (CH340G)

- Drivers

- GitHub Hardware Repo

SparkFun Serial Basic Breakout - CH340G Product Help and Resources

How to Install CH340 Drivers

August 6, 2019

How to install CH340 drivers (if you need them) on Windows, Mac OS X, and Linux.

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Rookie - You may be required to know a bit more about the component, such as orientation, or how to hook it up, in addition to power requirements. You will need to understand polarized components.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3.7 out of 5

Based on 7 ratings:

1 of 1 found this helpful:

An Improvement over USB to Serial breakouts

This breakout is awesome. It is a bit cheaper than the FTDI breakouts and the drivers are detected without issue on Windows (Win10 at least), versus the many issues I've had with drivers for the FTDI breakouts. Otherwise, everything else is up to snuff.

2 of 2 found this helpful:

Works as advertised

This board is working fine for me. I've used it on both Mac (OSX 10.11.3 El Capitan) and Windows 7. I did find it necessary to load the device driver onto both computers. The LEDs that indicate TX and/or RX traffic are a useful feature.

1 of 1 found this helpful:

No problems using Ubuntu 18.04 and pyserial

I thought that there was a problem with the linux kernel driver, but after using python to talk to the ch340g from a ch340c determined that there was no problem. I was able to transmit and receive at 9600, 115200 and 921600.

1 of 1 found this helpful:

Cause of so many headaches!

I don't know how this board works for some folks (it has good reviews). I bought this along with a SparkFun Edge Board in order to program and monitor output through the UART. I had so many issues with drivers and trying so many different approaches to get this to work (tried both under Linux 18LTS and MacOSX 10.15), Once I "thought" I solved the driver issues, I could not connect at any baud rate. I eventually switched over to an FTDI board (FT232L-based, with selectable 3.3/5V interface Vcc) which JUST WORKED! I will never get one of these WCH-based products again! The FTDI products are just so much better supported, from my vantage point.

2 of 4 found this helpful:

Doesn't seem to work on linux

I tried to compile the linux driver on my raspberry pi:

Linux rpi 4.9.27-v7+ #997 SMP Tue May 9 19:58:37 BST 2017 armv7l GNU/Linux

Didn't work. I googled around and it appears the driver isn't compatible with newer 4.x kernels. I suggest you just buy a real FTDI board so you don't have to deal with this.

it works without any driver work on 4.4.5 for me, and at 5V also

seems like some of the other sparkfun USB-Serial adapters don't work at 5V for some production runs at least, ao at the moment I like this one best

No M1 Mac drivers for CH340x

Beware that there don't currently (September 2022) seem to be drivers that will drive this for AppleSilicon (M1, etc.) Mac.

There's a possibility that some drivers are out there if you want to download from Github comments and can read Chinese, but if you expect to use this from a newish Mac, maybe look for a board with a different chip.

Try the one linked here https://cdn.sparkfun.com/assets/learn_tutorials/8/4/4/CH341SER_MAC.ZIP

What's up with the quarter on this one? :)

Man, it looks like a leftover from the Roman Empire... didn't know George Washington was that old! ;-)

This serial basic appears to work fine provided the target board has a clock with good tolerance. I found sketch uploads fail when using this serial basic with an 8MHz target board (ATmega328P using the internal clock) that has a clock that is off by more than about 2% (+2.25% in my case). With this same board I tried two different CH340G serial basics and both failed to upload while an FTDI serial basic uploads with no problem.

I don't suppose you'll offer a version of this CH340G breakout that includes the missing pins? I got this and didn't realize it breaks out the DTR instead of RTS pin. I needed CTS/RTS instead of CTS/DTR.

Made it work but the SMD chip soldering was a PITA and at one point I feared I had ripped the leg off the chip in the process.

How do I set the jumper to switch to 5 volts?

You will need to remove the blob of solder currently on the jumper (I usually double check with a multimeter or something to make sure it is fully disconnected). Then add a similar blob of solder connecting the middle pad to the 5V side. Basically the middle pad is connected to the VCC output on the board and the blob of solder is connecting that pad to either 3.3V or 5V.

Will this work with the Sparkfun Oscilloscope clock y'all used to sell?

Oh! I loved the old O-scope clock. Looking at the schematic for the oscilloscope clock I believe the pinout matches the CH340G Serial Basic so it should work quite nicely.

I'm sad that you wen't to micro USB. Every Dev board I have from sparkfun with Micro USB on it has broken off at sometime =(

:/ That's a bummer to hear. We've changed the microB connector and footprint significantly over the last few years to improve stability. I wouldn't design with it if I wasn't confident in it. I'm sorry to hear you've had some broken units. By all means let customer service know - we will certainly replace anything defective.