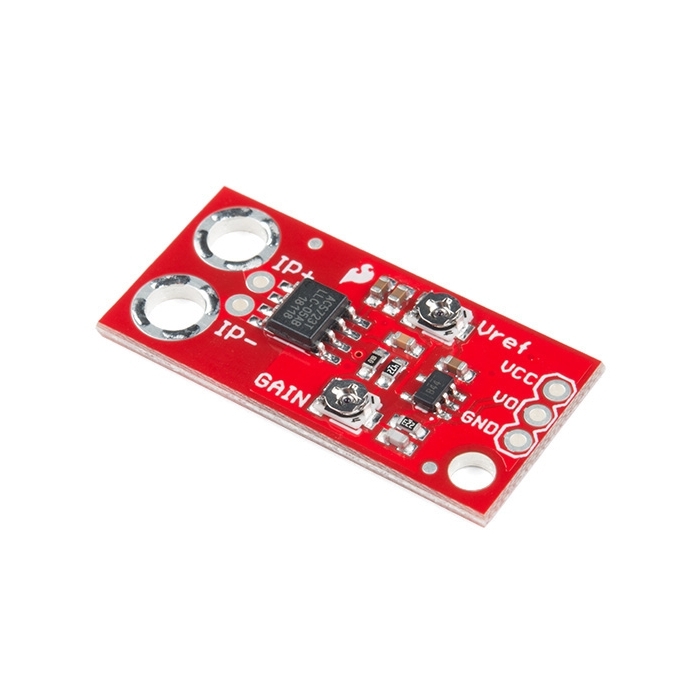

SparkFun Current Sensor Breakout - ACS723 (Low Current)

The low current version of the SparkFun Current Sensor Breakout is a high accuracy board that utilizes the ACS723 for low to moderate sensing applications.

Product Overview

This current sensor gives precise current measurement for both AC and DC signals. These are good sensors for metering and measuring overall power consumption of systems. The ACS712 current sensor measures up to 5A of DC or AC current. We added an opamp gain stage for more sensitive current measurements. By adjusting the gain (from 4.27 to 47) you can measure very small currents.

The ACS712 Low Current Sensor Breakout outputs an analog voltage that varies linearly with sensed current. To calibrate, first set the output offset to the desired level (with zero current on the sense lines, read output with a DVM). Then with a known current input (a 100mA limited supply works well for this), set the output deflection with the gain pot. Sensitivity is then calculated as (Vref - Vdeflect)/(current input).

The bandwidth on the ACS712 Low Current Sensor Breakout has been set to 34kHz to reduce noise when using at high gains. The full 80KHz bandwidth that the sensor is capable of can be recovered by removing C1. See schematic for more details.

Documents:

Documentation

- Schematic

- Eagle Files

- Hookup Guide

- Datasheet (ACS723)

- GitHub

Customer Reviews

Hookup Guide

Hookup Guide Schematic

Schematic Datasheet

Datasheet