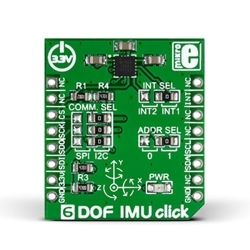

MIKROE 6DOF IMU 4 Click

6DOF IMU 4 Click is based on the ICM-20602, a high-performance, 6-axis MEMS MotionTracking™ IC from TDK Invensense.

Product Overview

6DOF IMU 4 Click is an advanced 6-axis motion tracking Click board™, which utilizes the ICM-20602, a high-performance integrated motion sensor, equipped with a 3-axis gyroscope, and a 3-axis accelerometer. There is a MEMS on each axis, sampled by a 16-bit A/D converter (ADC). Data streams from each axis are fed to a signal processing engine, offering calibrated readings of each axis over the I2C or SPI interface. A FIFO buffer with 1kb of memory allows MCU firmware optimization. Packed with a set of powerful options, this Click board™ represents an ideal solution for development of MotionTracking™ applications.

6DOF IMU 4 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development.

Features such as low power consumption, high precision of motion detection, high shock tolerance up to 20,000 g, a programmable full-scale range for increased accuracy, allow 6DOF IMU 4 Click to be used for development of different types of motion detection and MotionTracking™ applications: motion-based game controllers, 3D and gesture controllers, IoT applications, wearable motion sensing applications, and similar applications.

6DOF IMU 4 Click is based on the ICM-20602, a high-performance, 6-axis MEMS MotionTracking™ IC from TDK Invensense. It is an advanced, integrated microelectromechanical gyroscope and accelerometer sensor (MEMS). The ICM-20602 is produced using the patented CMOS-MEMS fabrication platform, specialized in MEMS production and its integration with accompanying logic sections, on a wafer level. This allows very high integration and very small dimensions, at an affordable cost. The IC contains a separate accelerometer and gyroscope MEMS on each axis. The output of each MEMS is processed and digitized by a separate sigma-delta 16-bit A/D converter (ADC).

Three-axis gyroscope MEMS can be programmed to measure the rotation about each axis, in four different ranges of rotational speed (degrees per angle, DPS): ±250, ±500, ±1000, and ±2000. Three-axis accelerometer MEMS can be programmed to measure the acceleration along each axis, in four different acceleration ranges: ±2g, ±4g, ±8g, and ±16g. The user can select an optimal range for both properties, depending on the application requirements.

The ICM-20602 incorporates a powerful programmable interrupt engine. The interrupt engine can generate a signal on the interrupt pin for several interrupt sources, including FIFO Buffer overflow, Data Ready, I2C Controller Error, and I2C Peripheral Error. The interrupt is routed to the INT pin of the mikroBUS™.

A FIFO buffer helps to further reduce the processing load, offering temporary storage for the output data. The MPU6050 features a FIFO buffer with the capacity of 1024 bytes. The user can select which data will be stored in the FIFO buffer: gyro data, accel data, temperature readings, and auxiliary sensor readings. Once the FIFO buffer is full, it will start discarding the oldest data, allowing new data to be written. The FIFO buffer overflow condition can be used to trigger an interrupt, alerting the host MCU about its status.

Synchronization with an external digital signal is possible over the FSYNC pin. This pin is routed to the PWM pin of the mikroBUS™, labeled as SYN. The ICM-20602 can be programmed to trigger an interrupt on the FSYN pin activity. The polarity of the signal pulse applied at the FSYN pin can also be programmed.

6DOF IMU 4 Click supports both SPI and I2C communication interfaces, allowing it to be used with a wide range of different MCUs. The communication interface can be chosen by moving SMD jumpers grouped under the COM SEL to an appropriate position (SPI or I2C). The peripheral I2C address can also be configured by a SMD jumper, when the Click board™ is operated in the I2C mode: a SMD jumper labeled as ADD SEL is used to set the least significant bit (LSB) of the I2C address. When set to 1, the 7-bit I2C peripheral address becomes 0b1101000x. If set to 0, the address becomes 0b1101001x. The last digit (x) is the R/W bit.

This Click board™ uses both I2C and SPI communication interfaces. It is designed to be operated only with 3.3V logic levels. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

Features & Specs

- Interface: I2C, SPI

- Compatibility: mikroBUS™

- Dimensions: 42.9 x 25.4mm

- Input Voltage: 3.3V

Documentation

Customer Reviews

Stock and Customer Discounts

Available Discounts

- $20.85 | 25+ units

- $19.76 | 100+ units