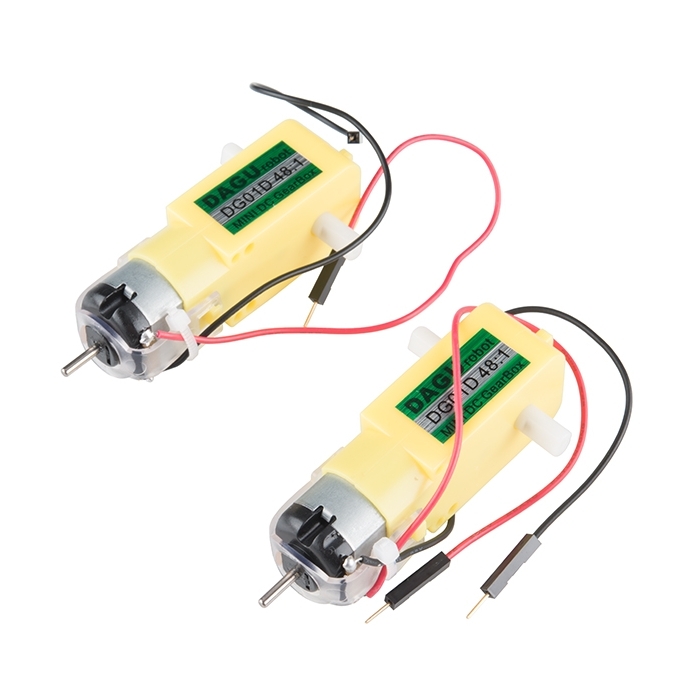

Hobby Gearmotor - 140 RPM (Pair)

ROB-13302

Hobby Gearmotor - 140 RPM (Pair)

SKU: ROB-13302

$7.50

In stock

SKU

ROB-13302

Helpful Documentation

Product Overview

These are a pair of hobby gearmotors from DAGU. These gearmotors are the same ones recommended for use in the Shadow Chassis and offer a cheap and easy-to-use setup to get your wheels turning. Each Hobby Gearmotor also possess a 9mm long output on a straight axis.

These gearmotors require a voltage of 4.5V with a no load current of 190mA while possessing a gearbox ratio of 48:1 and a wheel speed of 140 RPM unloaded.

Every motor order is sold in packs of two.

Note: The RPM listed in the datasheet below is listed as 90RPM. Based on our own testing we found the gearmotors can actually achieve a No Load Speed of about 140 RPM.

Features:

- Suggested Voltage: 4.5VDC

- No Load Speed: 140RPM

- No Load Current: 190mA

- Max. Load Current: 250mA

- Torque: 800 gf-cm

Documents:

- Datasheet (DG01D)

Hookup Accessories

Features & Specs

- Suggested Voltage: 4.5VDC

- No Load Speed: 140RPM

- No Load Current: 190mA

- Max. Load Current: 250mA

- Torque: 800 gf-cm

Documentation

- Datasheet (DG01D)

Customer Reviews

Hobby Gearmotor - 140 RPM (Pair)

$7.50

ROB-13302

Stock and Customer Discounts

$7.5 retail price.

Available Discounts

- $7.13 | 25+ units

- $6.75 | 100+ units

Datasheet (DG01D)

Datasheet (DG01D)