bboyho

Member Since: August 22, 2011

Country: United States

Profile

Bio

Engineer by day, bboy by night.

Organizations

Worm Tank Crew

Blowup Kingz

Block1750

Universities

Electrical & Computer Engineering, Dec. 2011

College of Engineering and Applied Science

University of Colorado at Boulder

Websites

Today we have a special treat for you - a sneak preview of one of our latest products before we release it! See why all our testers gave it five stars...

Check out some of our recent Pi tutorials to get started with Raspberry Pi, the RP2040, Qwiic and more!

Using the Qwiic pHAT v2.0's general purpose button to safely reboot or shutdown your Raspberry Pi with the help of a Python script.

Comparing analog and digital temperature sensors TMP36, TMP102 and TMP117. Which is better?

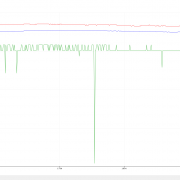

We updated some code for the micro:bot kit to help debug and interpret line following sensor readings using the MakeCode Console.

Deck out your Sphero RVR robot with a Raspberry Pi Zero W, remote pan-tilt camera, and some Qwiic components!

What do you do after the SparkFun Inventor's Kit for Arduino? Here are a few more tutorials to help take your projects to the next level!

What do you do after the SparkFun Inventor's Kit? The RedBoard Qwiic in your kit offers a world of opportunities – here are a few tutorials to help you dive into the Qwiic ecosystem with your SIK!

What do you do after the SparkFun Inventor's Kit? The world of electronics using Arduino is vast – here are a few tutorials to help take your projects to the next level!

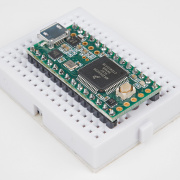

Are you new to the Teensy product line? Make sure to check out our Getting Started with Teensy tutorial before adding this powerful microcontroller to your project!

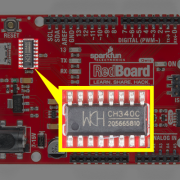

USB-to-serial UART bridges like the CH340 make it easier to upload code to an Arduino and pass serial data to/from your computer. Make sure to install the respective drivers before getting started.

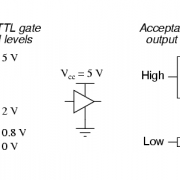

Learn what a logic level is, and how to interface between different technologies, with a few of our tutorials!

How do you work with wire? Level up your technical skills by checking out this tutorial.

Control a robot wirelessly with your hand using XBees, Arduino and an accelerometer.

Using EL once again for my students' performance using a glove controller, XBees, EL sequencers and Arduino.

Control your RedBot programmed with Arduino using the wireless joystick and a pair of XBees!

Let's check out my third design to control LEDs based on movement using an accelerometer!

Lumos! Here are my experiences 3D-printing a "magical" illuminated wand theatrical prop for my students' performance.

Prototype interactive dance floor using the Teensy's built-in capacitive touch pins and XBee Series 1s configured for I/O line passing.

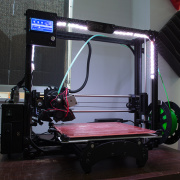

Try adding a LED strip to your 3D printer for better lighting with this quick and simple solution!

Diamonds are... forever? My experiences 3D printing a translucent diamond theatrical prop for a choreographed piece with LEDs and capacitive touch sensing.

Build a custom wireless audio Bluetooth adapter using BlueCreation's BC127 and add it to your old speaker system!

Not working as expected? Luckily, we have a tutorial about where to start looking and will explore a few general troubleshooting tips that frequently come up in SparkFun’s technical support department!

Today, we revisit the concept of serial communication with RS-232 and TTL. We'll also explore the "inverted TTL" with the ultrasonic range finder to read data from the sensor.

Single Cell LiPo Battery Care

March 16, 2023

This tutorial will go over how to safely charge, connect, disconnect, reinforcing the cables, and handle single cell LiPo batteries.

LiPo Fuel Gauge (MAX1704X) Hookup Guide

February 23, 2023

Monitor your LiPo battery with the LiPo fuel gauge! In this tutorial, we will be using the MAX17043 and MAX17048 to monitor a single cell, LiPo battery over the Arduino Serial Monitor. We will also connect a display to view the output without the need to connect the microcontroller to a computer.

Analog MEMS Microphone (VM2020) Hookup Guide

February 9, 2023

Get started with the SparkFun analog MEMS microphone breakout board! In this tutorial, we will be connecting the differential MEMS microphone to an Arduino using the WM8960 audio codec.

Audio Codec Breakout - WM8960 Hookup Guide

January 26, 2023

The SparkFun Audio Codec Breakout - WM8960 is a low power, high quality stereo codec chock full of features. In this tutorial, some of these features by using an Arduino microcontroller to configure the audio codec and pass audio to the headphone or speaker channels.

Getting Started with u-blox Thingstream and PointPerfect

January 23, 2023

Interested in high precision GNSS without setting up a base station?

MicroMod Main Board Hookup Guide V2

January 5, 2023

The MicroMod Main Board - Single and Double are specialized carrier boards that allow you to interface a Processor Board with a Function Board(s). The modular system allows you to add an additional feature(s) to a Processor Board with the help of a Function Board(s). In this tutorial, we will focus on the basic functionality of the Main Board - Single V2.1 and Main Board - Double and V2.2.

Qwiic Kit for Raspberry Pi V2 Hookup Guide

December 29, 2022

Get started with the SGP40, BME280, VCNL4040, and microOLED via I2C using the Qwiic system and Python on a Raspberry Pi! Measure VOC Index, light, temperature, humidity, and pressure from the environment. Then display them on the microOLED, serial terminal, or the cloud with Cayenne!

GNSS Correction Data Receiver (NEO-D9S) Hookup Guide

October 27, 2022

Add GNSS correction data to your high precision GNSS (HPG) receiver with the u-blox NEO-D9S! This tutorial will get you started with the ZED-F9P, NEO-D9S, and the ESP32 IoT RedBoard.

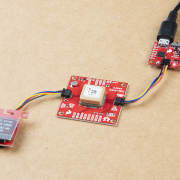

MicroMod Qwiic Pro Kit Project Guide

September 29, 2022

The MicroMod Qwiic Pro Kit was designed to allow users to get started with Arduino without the need for soldering or a breadboard. We've included three inputs (a joystick, accelerometer, and proximity sensor) and one display that can be daisy chained to the MicroMod SAMD51 Processor Board.

Qwiic Speaker Amp (TPA2016D2) Hookup Guide

September 29, 2022

The SparkFun Qwiic Speaker Amp includes the Texas Instruments TPA2016D2 stereo, filter-free class-D audio power amplifier. This tutorial will help you get started and configure the amplifer settings using an Arduino microcontroller.

AzureWave Thing Plus (AW-CU488) Hookup Guide

September 22, 2022

The SparkFun AzureWave Thing Plus is a Feather form-factor development board equipped with the AW-CU488. We'll highlight key features of the board and show you to get started with the development board. A few Arduino examples will be highlighted to connect to a WiFi router, calculate the Fast Fourier Transform (FFT) from an input microphone, output an analog signal to a speaker, and connect an Qwiic-enabled device.

GNSS Receiver Breakout - MAX-M10S (Qwiic) Hookup Guide

September 1, 2022

Get started using the SparkFun GNSS Receiver Breakout - MAX-M10S (Qwiic), a ultra-low power, GNSS receiver module for your asset tracking needs!

MicroMod GNSS Function Board - NEO-M9N Hookup Guide

August 11, 2022

The u-blox NEO-M9N is a powerful GPS unit that now comes populated on a MicroMod Function Board! In this tutorial, we will quickly get you set up using it with the MicroMod ecosystem and Arduino so that you can start reading the output.

Qwiic Digital Desk Sign with MicroMod

June 30, 2022

Make a Qwiic-enabled digital desk sign with a MicroMod SAMD51 Processor Board's USB Host and a USB keyboard!

Qwiic dToF Imager (TMF882X) Hookup Guide

April 14, 2022

Getting started with the AMS dToF imagers (TMF8820 and TMF8820).

Getting Started with the MyoWare® 2.0 Muscle Sensor Ecosystem

April 1, 2022

The MyoWare® 2.0 Muscle Sensor, an Arduino-compatible, all-in-one electromyography (EMG) sensor from Advancer Technologies. In this tutorial, we will go over the features and related shields to connect the sensor to a muscle group.

Qwiic Distance Sensor (VL53L1X, VL53L4CD) Hookup Guide

February 10, 2022

The Qwiic Distance Sensor - VL53L1X is a time of flight sensor that is capable of several modes, as well as having a range of 4M. It's cousin VL53L4CD is also a time of flight sensor with similar characteristics but it has a range of about 1.3M. Let's hook it up and find out just how far away that thing over there is.

SparkFun GPS-RTK Dead Reckoning ZED-F9K Hookup Guide

January 6, 2022

The u-blox ZED-F9K is a powerful GPS-RTK unit that uses a fusion of IMU, wheel ticks, a vehicle dynamics model, correction data, and GNSS measurements to provide highly accurate and continuous position for navigation in the difficult conditions. We will quickly get you set up using the Qwiic ecosystem through Arduino so that you can start reading the output!

MicroMod GNSS Carrier Board (ZED-F9P) Hookup Guide

December 9, 2021

Easily switch between Processor Boards using the MicroMod ecosystem and get precision down to the diameter of a dime with the ZED-F9P from u-blox using the MicroMod GNSS Carrier Board!

MicroMod WiFi Function Board - ESP32 Hookup Guide

November 11, 2021

The MicroMod ESP32 Function Board adds additional wireless options to MicroMod Processor Boards that do not have that capability. This special function board acts as a coprocessor that takes advantage of Espressif's ESP32 WROOM to add WiFi and Bluetooth® to your applications.

MicroMod Main Board Hookup Guide

November 11, 2021

The MicroMod Main Board - Single and Double are specialized carrier boards that allow you to interface a Processor Board with a Function Board(s). The modular system allows you to add an additional feature(s) to a Processor Board with the help of a Function Board(s). In this tutorial, we will focus on the basic functionality of the Main Board - Single and Main Board - Double.

MicroMod Environmental Function Board Hookup Guide

November 11, 2021

The SparkFun MicroMod Environmental Function Board adds additional sensing options to the MicroMod Processor Boards. This function board includes three sensors to monitor air quality (SGP40), humidity & temperature (SHTC3), and CO2 concentrations (STC31) in your indoor environment. To make it even easier to use, all communication is over the MicroMod's I2C bus! In this tutorial, we will go over how to connect the board and read the sensors.

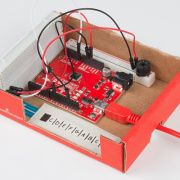

Tinker Kit Circuit Guide

September 16, 2021

This guide takes you through the basics of building 11 different circuits with the SparkFun Tinker Kit and how to program them using the Arduino IDE.

QuickLogic Thing Plus (EOS S3) Hookup Guide

July 22, 2021

This guide provides users with functional descriptions, configuration options for the QuickLogic Thing Plus EOS S3. It also serves as a “Getting Started” and “How To” guide.

RedBoard Plus Hookup Guide

July 1, 2021

This tutorial covers the basic functionality of the RedBoard Plus. This tutorial also covers how to get started blinking an LED and using the Qwiic system.

Qwiic 6DoF (LSM6DSO) Breakout Hookup Guide

May 20, 2021

A hookup guide for the Qwiic 6DoF (LSM6DSO), which features a 3-axis accelerometer, 3-axis gyroscope, temperature sensor, and FIFO buffer.

Qwiic Haptic Driver DA7280 Hookup Guide

April 29, 2021

The Qwiic Haptic Driver includes an itty-bitty, Linear Resonant Actuator (LRA) vibration motor and Dialog Semiconductor's DA7280 motor driver IC for applications that require haptic feedback.

Qwiic MultiPort Hookup Guide

April 1, 2021

The SparkFun Qwiic MultiPort adds additional ports to boards that have only one Qwiic port on their I2C bus. Once added, you can use it as a hub to add as many I2C devices to the bus as you need! You can also use the board as an alternative to a daisy chained configuration.

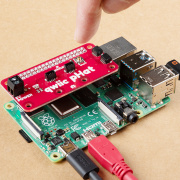

Qwiic SHIM Kit for Raspberry Pi Hookup Guide

February 16, 2021

Get started with the Serial LCD with RGB backlight and 9DoF IMU (ICM-20948) via I2C using the Qwiic system and Python on a Raspberry Pi! Take sensor readings and display them in the serial terminal or SerLCD.

Pro Micro RP2040 Hookup Guide

January 21, 2021

This tutorial covers the basic functionality of the Pro Micro RP2040 and highlights the features of the dual-core ARM Cortex-M0+ processors development board. Get started with the first microcontroller from the Raspberry Pi Foundation!

MicroMod RP2040 Processor Board Hookup Guide

January 21, 2021

This tutorial covers the basic functionality of the MicroMod RP2040 Processor Board and highlights the features of the dual-core ARM Cortex-M0+ processors development board. Get started with the first microcontroller from the Raspberry Pi Foundation!

Qwiic pHAT Extension for Raspberry Pi 400 Hookup Guide

December 17, 2020

Get started interfacing your Qwiic enabled boards with your Raspberry Pi 400! SparkFun Qwiic pHAT Extension for the Raspberry Pi 400 provides you with a quick and easy solution to access all of the 400's GPIO, stack your favorite HAT right-side up, or connect a Qwiic-enabled device to the I2C bus (GND, 3.3V, SDA, and SCL).

MicroMod All The Pins (ATP) Carrier Board

October 21, 2020

Access All The Pins (ATP) of the MicroMod Processor Board with the Carrier Board!

MicroMod SAMD51 Processor Board Hookup Guide

October 21, 2020

This tutorial covers the basic functionality of the MicroMod SAMD51 and highlights the features of the ARM Cortex-M4F development board.

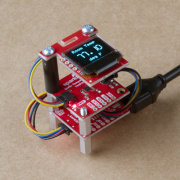

Qwiic GPS Clock

September 14, 2020

What time is it? Time for you to... Qwiic-ly build a GPS clock and output it to a display! This project provides you with the current date and time using GPS satellites. Read the date and time as a digital or analog clock. Or even configure the clock for military, your time zone, or automatically adjust the time for daylight savings time!

OpenLog Artemis Hookup Guide

August 20, 2020

How to use and re-program the OpenLog Artemis, an open source datalogger. The OLA comes preprogrammed to automatically log data. The OLA can also record serial data, analog voltages, or readings from external Qwiic-enabled I2C devices. Some of these Qwiic-enabled devices include GPS/GNSS modules, pressure, altitude, humidity, temperature, air quality, environment, distance, and weight sensors.

Qwiic Digital Indoor Thermometer

July 15, 2020

Qwiic-ly build a digital indoor thermometer to measure the ambient temperature of the room and display it using an OLED on an I2C bus!

SparkFun GPS-RTK Dead Reckoning ZED-F9R Hookup Guide

July 9, 2020

The u-blox ZED-F9R is a powerful GPS-RTK unit that uses a fusion of IMU, wheel ticks, a vehicle dynamics model, correction data, and GNSS measurements to provide highly accurate and continuous position for navigation in the difficult conditions. We will quickly get you set up using the Qwiic ecosystem through Arduino and Python so that you can start reading the output!

Wireless Remote Weather Station with micro:bit

May 11, 2020

Monitor the weather without being exposed to it through wireless communication between two micro:bits using the radio blocks! This is useful if your weather station is installed in a location that is difficult to retrieve data from the OpenLog. We will also explore a few different ways to send and receive data.

SparkFun GPS Dead Reckoning NEO-M8U Hookup Guide

April 30, 2020

The u-blox NEO-M8U is a powerful GPS units that takes advantage of untethered dead reckoning (UDR) technology for navigation. The module provides continuous positioning for vehicles in urban environments and during complete signal loss (e.g. short tunnels and parking garages). We will quickly get you set up using the Qwiic ecosystem and Arduino so that you can start reading the output!

Raspberry Pi Safe Reboot and Shutdown Button

April 20, 2020

Safely reboot or shutdown your Raspberry Pi to avoid corrupting the microSD card using the built-in general purpose button on the Qwiic pHAT v2.0!

Temperature Sensor Comparison

March 18, 2020

A comparison of analog and digital temperature sensors. Which is better?

Raspberry Pi 4 Kit Hookup Guide

March 14, 2020

Guide for hooking up your Raspberry Pi 4 Model B basic, desktop, or hardware starter kit together.

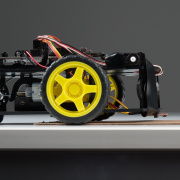

micro:bot Kit Experiment Guide

February 20, 2020

Get started with the moto:bit, a carrier board for the micro:bit that allows you to control motors, and create your own robot using this experiment guide for the micro:bot kit.

Non-Addressable RGB LED Strip Hookup Guide

February 19, 2020

Add color to your projects with non-addressable LED strips! These are perfect if you want to control and power the entire strip with one color for your props, car, fish tank, room, wall, or perhaps under cabinet lighting in your home.

Qwiic Pro Micro USB-C (ATmega32U4) Hookup Guide

February 6, 2020

An overview of the ATmega32U4-based Qwiic Pro Micro USB-C, how to install it, and how to use it with Arduino.

RED-V Development Guide

November 27, 2019

This guide will help you get the RED-V RedBoard or Thing Plus up and running for the exhaust port. Depending on personal preference, there are a few environments to get started with the boards. All wings report in... we're going in full-throttle.

RED-V RedBoard Hookup Guide

November 22, 2019

This guide will go over the hardware of the RED-V RedBoard.

RED-V Thing Plus Hookup Guide

November 22, 2019

This guide will go over the hardware of the RED-V Thing Plus.

Qwiic TMP117 High Precision Digital Temperature Sensor Hookup Guide

November 14, 2019

Add a high precision, digital temperature sensor to your projects using the TMP117 over the I2C!

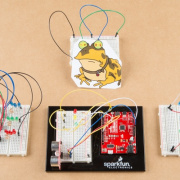

Qwiic Pro Kit Project Guide

November 7, 2019

The Qwiic Pro Kit was designed to allow users to get started with Arduino without the need for soldering or a breadboard. We've included three inputs (a joystick, accelerometer, and proximity sensor) and one display that can be daisy chained to the RedBoard Turbo (SAMD21) Development Board.

Wireless Controlled Wearable EL Wire Dance Suit

October 31, 2019

In this tutorial, we will build an EL wire dance suit that can be controlled by a wireless glove controller!

SparkFun Qwiic Micro (SAMD21E) Hookup Guide

October 24, 2019

An introduction to the Qwiic Micro SAMD21E. Level up your Arduino-skills with the powerful SAMD21 ARM Cortex M0+ processor!

ATX Power Connector (4-Pin) Breakout Hookup Guide

October 10, 2019

Do you need to power a project with 12V and 5V from one wall adapter? The ATX power connector breaks out the standard 4-pin computer peripheral port for your 12V and 5V devices!

APA102 Addressable LED Hookup Guide

October 8, 2019

Connect, power, and control your APA102 addressable LED strip!

Fuse Breakout Board Hookup Guide

October 3, 2019

Protect your project by adding a fuse in your circuit to save it from molten destruction.

Getting Started with the A111 Pulsed Radar Sensor

September 26, 2019

Get started with the Acconeer A111 SDK with a Raspberry Pi! The tiny A111 pulsed coherent radar (PCR) adds high-precision, cutting-edge distance measurement for speed-, material-, motion-, or gesture-sensing projects! We’re not talking about simple ultrasonic, or even infrared sensors here, but 60GHz radar!

SparkFun Inventor's Kit Experiment Guide - v4.1

August 8, 2019

The SparkFun Inventor's Kit (SIK) Experiment Guide contains all of the information needed to build all five projects, encompassing 16 circuits, in the latest version of the kit, v4.1.2 and v4.1.

How to Install CH340 Drivers

August 6, 2019

How to install CH340 drivers (if you need them) on Windows, Mac OS X, and Linux.

PCA9306 Logic Level Translator Hookup Guide (v2)

July 25, 2019

A quick primer to get you going with the PCA9306 Logic Level Converter - a dedicated I2C translator.

LilyPad RGB LED Hookup Guide

July 18, 2019

Learn how to hook up the LilyPad RGB LED and use a common cathode RGB LED in e-textile projects.

Modifying Your EL Wire Inverter

July 18, 2019

In this tutorial, we will modify the 12V EL wire inverter to power the EL Sequencer/EL Escudo Dos off a single power supply.

EL Wire Pants

July 18, 2019

In this tutorial, we will sew standard electroluminescent (EL) wire to a pair of pants.

Basic Character LCD Hookup Guide

May 28, 2019

Liquid crystal displays (LCDs) are a great way to output a string of words or sensor data to a display for visual feedback. In this tutorial, we'll learn about LCDs, how to print a string of words to a 16x2 basic character LCD and create custom characters.

Qwiic pHAT for Raspberry Pi Hookup Guide

May 23, 2019

Get started interfacing your Qwiic enabled boards with your Raspberry Pi. The Qwiic pHAT connects the I2C bus (GND, 3.3V, SDA, and SCL) on your Raspberry Pi to an array of Qwiic connectors.

Wireless Gesture Controlled Robot

April 25, 2019

Control the RedBot wirelessly based on the movement of your hand using an accelerometer, Arduino, and XBees!

Wireless Glove Controller

April 24, 2019

Build a wireless glove controller with Arduinos to trigger an LED using XBees!

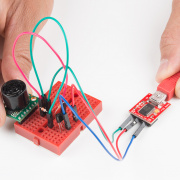

Beginner Parts Kit Identification Guide

March 22, 2019

The essential parts for beginning (or even experienced) hobbyists that gives you all of the basic through-hole components you will need to get started playing with embedded projects. We'll identify a few parts in the kit and provide a few basic circuits to get started!

RHT03 (DHT22) Humidity and Temperature Sensor Hookup Guide

March 12, 2019

Measure relative humidity and temperature or your environment with the RHT03 (a.k.a DHT22) low cost sensor on a single wire digital interface connected to an Arduino!

Wireless RC Robot with Arduino and XBees

March 12, 2019

In this tutorial, we will expand on the SIK for RedBot to control the robot wirelessly with XBee radios! We'll explore a different microcontroller and wirelessly control the RedBot at a distance.

Thumb Joystick Hookup Guide

February 20, 2019

Whether you're blasting aliens, driving a robot, or write your awesome classic Arcade Game for your Arduino, you'll find the analog thumb joystick a very useful addition to your projects!

Motion Controlled Wearable LED Dance Harness

January 30, 2019

Control LEDs based on your movement using an accelerometer! Make your LEDs breathe by fading in and out when laying on the floor, turn off the LEDs when moving to your side, or make the LEDs blink in a headstand!

Wireless Remote Control with micro:bit

January 21, 2019

In this tutorial, we will utilize the MakeCode radio blocks to have the one micro:bit transmit a signal to a receiving micro:bit on the same channel. Eventually, we will control a micro:bot wirelessly using parts from the arcade:kit!

LilyPad Vibe Board Hookup Guide

January 16, 2019

The LilyPad Vibe Board is a small vibration motor that can be sewn into projects with conductive thread and controlled by a LilyPad Arduino. The board can be used as a physical indicator on clothing and costumes for haptic feedback.

LS20031 5Hz (66 Channel) GPS Receiver Hookup Guide

December 13, 2018

In this tutorial, we will solder headers to the surface mount pads of the LS20031 GPS receiver and read the output using an Arduino!

3D Printed Illuminated Wand Prop

November 29, 2018

In this tutorial, we will learn about how to create a theatrical prop for a performance by 3D printing a wand and adding an LED.

Getting Started with the SmartLED Shield for Teensy

November 9, 2018

In this tutorial, we will connect different RGB LED matrix panels to PixelMatix's SmartLED shield and Teensy.

TFMini - Micro LiDAR Module (Qwiic) Hookup Guide

November 8, 2018

The TFMini is a ToF (Time of Flight) LiDAR sensor capable of measuring the distance to an object as close as 30 cm and as far as 12 meters! The TFMini allows you to easily integrate LiDAR into applications traditionally reserved for smaller sensors such as the SHARP GP-series infrared rangefinders. With the added Qwiic feature, you can quickly connect to the sensor via I2C!

How to Make a Custom EL Wire Extension Cable

October 24, 2018

In this tutorial, we will make a custom EL Wire extension cable as an alternative to splicing wire.

EL Wire Hoodie

October 24, 2018

In this tutorial, we will sew standard electroluminescent (EL) wire to a hoodie.

Single Supply Logic Level Converter Hookup Guide

August 9, 2018

The Single Supply Logic Converter allows you to bi-directionally translate signals from a 5V or 3.3V microcontroller without the need for a second power supply! The board provides an output for both 5V and 3.3V to power your sensors. It is equipped with a PTH resistor footprint for the option to adjust the voltage regulator on the low side of the TXB0104 for 2.5V or 1.8V devices.

Getting Started with Electroluminescent (EL) Wire

July 13, 2018

This guide will help you get started with electroluminescent (EL) wire, tape, panel, chasing wire, and bendable wire to let your project glow!

Mean Well LED Switching Power Supply Hookup Guide

June 28, 2018

In this tutorial, we will be connecting a Mean Well LED switching power supply to an addressable LED strip controlled by an Arduino.

Light Up Your 3D Printer's Bed

June 27, 2018

Having issues viewing your print in a dark lit room? In this tutorial, we will be using LED strips to light up a print bed's area on a LulzBot 3D printer!

PIC-Based Serial Enabled Character LCD Hookup Guide

May 29, 2018

The PIC-based serial enabled character LCD backpack is a simple and cost effective solution for interfacing to character Liquid Crystal Displays (LCDs) based on the HD44780 controller. The backpack simplifies the number of wires needed and allows your project to display all kinds of text and numbers.

SparkFun Arduino ProtoShield Hookup Guide

May 17, 2018

The SparkFun Arduino ProtoShield PCB and ProtoShield kit lets you customize your own Arduino shield using whatever custom circuit you can come up with! This tutorial will go over its features, hardware assembly, and how to use the shield with an Arduino R3 footprint.

12V/5V Power Supply Hookup Guide

May 10, 2018

In this tutorial, we will replace the 12V/5V (2A) power supply's molex connector with two male barrel jacks adapters.

Interactive 3D Printed LED Diamond Prop

April 19, 2018

In this tutorial, we will learn about how to create an interactive theatrical prop for a performance by 3D printing a translucent diamond prop using a non-addressable RGB LED strip and AT42QT1011 capacitive touch sensing.

Addressable LED Neon Flex Rope Hookup Guide

April 19, 2018

The addressable (UCS1903) LED neon flex rope adds cool lighting effects for outdoor and indoor uses including in hallways and stairs, holiday lighting, and more! In this hookup guide, you will learn how to connect, power, and control the LED segments with an Arduino and the FastLED library.

TFMini - Micro LiDAR Module Hookup Guide

April 13, 2018

The TFMini is a ToF (Time of Flight) LiDAR sensor capable of measuring the distance to an object as close as 30 cm and as far as 12 meters! The TFMini allows you to integrate LiDAR into applications traditionally reserved for smaller sensors such as the SHARP GP-series infrared rangefinders.

How to Use a Hot Air Rework Station

April 10, 2018

Hot-air stations or heat guns are very useful tools and are essential for any electronics workbench. When working with or building printed circuit boards, there is a lot of room for errors to be made. Have no fear though, there are ways to remedy this with a hot air rework station!

How to Work with Jumper Pads and PCB Traces

April 2, 2018

Handling PCB jumper pads and traces is an essential skill. Learn how to cut a PCB trace, add a solder jumper between pads to reroute connections, and repair a trace with the green wire method if a trace is damaged.

Craft a Holiday Greeting with Love to Code

March 23, 2018

Craft your own paper circuit holiday greeting using the LEDs, a Chibi Chip, Love to Code!

Getting Started with Chibi Chip and Clip

March 22, 2018

This tutorial goes over the how to assemble the Chibitronics' Chibi Chip programmable microcontroller with the Chibi Clip to add more functionality to your paper circuits! Start programming your Chibi Chip by writing code (block-based and text-based) in a browser-based code editor and then transmit code through sound to your board!

Fingerprint Scanner (GT-521Fxx) Hookup Guide

March 1, 2018

This tutorial provides information about how to connect to ADH-Tech's fingerprint scanner (GT-521F32) and how to use it with Hawley's FPS_GT511C3 library for Arduino.

Getting Started with Walabot

February 15, 2018

See through walls, track objects, monitor breathing patterns, and more using the power of radio frequency with the Walabot! In this tutorial, we will explore Walabot’s features using the Software Demo Kit (SDK) on Windows and the Application Programming Interface (API) on Linux-based distributions for embedded projects.

Prototype Wearable LED Dance Harness

February 8, 2018

A project tutorial to add an extra effect for dancers performing a choreographed piece. The harness can be added quickly under a costume.

Makey Makey Classic Hookup Guide

January 11, 2018

Be stoked! The world is your construction kit. How to turn everyday objects into computer inputs with the Makey Makey Classic from JoyLabz.

Wireless Audio Bluetooth Adapter w/ BC127

December 14, 2017

Build a custom wireless audio Bluetooth adapter using BlueCreation's BC127 and add it to your old speaker system!

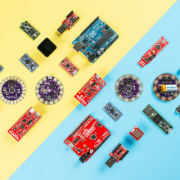

Choosing an Arduino for Your Project

December 11, 2017

Examining the diverse world of Arduino boards and understanding the differences between them before choosing one for a project.

SparkFun Troubleshooting Tips

October 19, 2017

Not working as expected? In this tutorial, we will be exploring a few general troubleshooting tips and possible solutions that frequently come up with SparkFun's Technical Support.

micro:climate Kit Experiment Guide

July 21, 2017

A weather station kit that is built on top of the inexpensive, easy-to-use micro:bit and Microsoft MakeCode.

SparkFun Inventor's Kit for micro:bit Experiment Guide

July 21, 2017

This guide contains all the information you will need to explore the twelve circuits of the SparkFun Inventors Kit for micro:bit.

micro:arcade Kit Experiment Guide

July 21, 2017

We love games! We love writing games, building games and yes, even building game consoles. So we want to introduce to you the micro:arcade kit for the micro:bit!

Force Sensitive Resistor Hookup Guide

May 5, 2016

How to hook a force-sensitive resistor up to an Arduino to measure pressure variances.

Flex Sensor Hookup Guide

May 5, 2016

An overview of the flex sensor - a bendable variable resistor. Plus, example circuits and Arduino code to get you started!

Pocket AVR Programmer Hookup Guide

July 7, 2014

Skip the bootloader and load your program directly onto an AVR with the AVR Pocket Programmer.

IR Control Kit Hookup Guide

October 2, 2013

How to get the most out of the infrared receivers and transmitters included in the IR Control Kit.

Light-Emitting Diodes (LEDs)

August 12, 2013

Learn the basics about LEDs as well as some more advanced topics to help you calculate requirements for projects containing many LEDs.

Installing Arduino IDE

March 26, 2013

A step-by-step guide to installing and testing the Arduino software on Windows, Mac, and Linux.

Simon Says Assembly Guide

January 20, 2011

No matter what flavor of the Simon Says Through-hole Soldering Kit you've purchased, this tutorial is here to guide you through the entire build process.

Simon Says Experiments

October 21, 2010

So you've built up a Simon Says kit? What next? This tutorial will get you up and running with Arduino software, guide you through a few example sketches, and send you on your way to create your own. Careful, this stuff is highly addictive. :)

-

Hmm, fiberglass is made up of plastic and glass so I would assume that there would be some loss in range similar to both of those materials. I'm not sure of the specifics since I have not tested the XM125 with fiberglass from an RV trailer. Acconeer lists some materials through their handbook along with some of their relative permittivity. However, they do not list the range.

It would be best to test to make sure and ensure that there is no metal between the sensor, fiberglass, and object that you are trying to detect. =)

-

No problem! Hopefully it works with your flavor of Linux. Acconeer lists "Ubuntu 20.04" as the Linux distribution.

-

There should be intructions in the readme.md if you are referring to the Acconeer Python Exploration Tool. You'll need to use a command line => https://github.com/acconeer/acconeer-python-exploration?tab=readme-ov-file#setting-up-your-local-machine.

-

Hi!

Sorry about the broken links (gray "slash box") last week with the Qwiic "Narrow" OLED Display's section. The images were in a different location and I was not able to test it until the tutorial & GitHub repos were live (just a chicken and egg problem x_X). I got them up by the end of one of the days last week so they should be good now.

As far as the board dimensions, the mounting holes included in SparkFun designs typically use the 4-40 screws. We usually don't think about that when writting the documentation but I can look into it with the others on the team.

-

Hi!

It looks like you can download the Serial Studio Software here => https://serial-studio.github.io/ .

-

Hi,

I don't believe there is a feature with the OpenLog Artemis to use with ThingSpeak. Try looking at the SparkFun DataLogger IoT. That board has the ability to connect to ThingSpeak.

-

Hi!

Sorry, I just saw your question. If your question has not been answered yet...

Unfortunately, no. As the product description states, it has "four plated through holes [that] are broken out for SCL, SDA, 3.3V and GND". This also includes two Qwiic connectors. This is to convert boards that do not have the Qwiic connectors built in. SparkFun breakout boards usually have built-in pull-up resistors so we do not include it on the board. This also reduces the cost of the board.

You could manually solder two through hole resistors using the plated through holes (probably 2.2kΩ resistors but it depends on your device and system) if you really need.

-

Hi!

I just noticed your comment. Sorry, the product is patent protected. To prevent counterfeit boards, the Eagle design files and GitHub hardware repository are not shared for boards in the MyoWare 2.0 ecosystem.

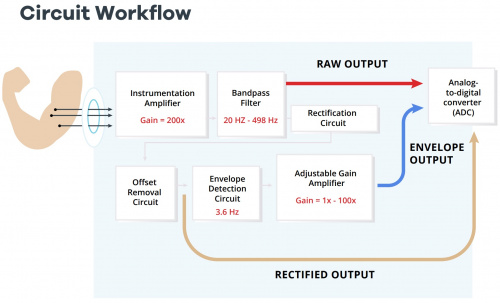

However, there is some information in the block diagrams. If you have not checked it out, be sure to look in the Getting Started with the MyoWare® 2.0 Muscle Sensor Ecosystem: MyoWare 2.0 Muscle Sensor and MyoWare Advanced Guide. There are a few stages to amplify, filter, rectify, and process the envelope.

-

Hi!

Ah, sorry about that. Our engineer is looking through them and has been updating the Python package. Your pull request was been accepted => https://github.com/sparkfun/Qwiic_Ublox_Gps_Py/commit/973952360467c343b0fa649b363d1099ed8a5351 .

Thank you for contributing. =)

-

Yeah sorry, we discontinued it from our catalog.

Hmm, not off the top of my head. Doing a little search online, it looks like they have some still available on the Elecktor's Store (I was able to view the shipping details at checkout but I'm not entirely sure where their distribution center is located?) => https://www.elektor.com/stemtera-arduino-uno-compatible-breadboard .

Or even try to contact STEMTera=> https://stemtera.com/.

Actobotics Slider with Stepper Motor Mount

Demo of the Actobotics Stepper Motor Mount on a slider using...