Jesse Brockmann is a senior software engineer with over 20 years of experience. Jesse works for a large corporation designing real-time simulation software, started programming on an Apple IIe at the age of six and has won several AVC event over the years. Jesse is also a SparkFun Ambassador. Make sure you read today's post to find out what he'll be up to next!

This is the second part of a multi-post series. If you would like to start from the beginning click here to see part one.

I would first like to respond to some comments I received on this project. I support and encourage the right to repair, and I can understand why people are upset with the current situation with newer equipment from John Deere or other companies. This mower was produced in a very different era and was very well documented by the owner's manual. For example, it included a complete circuit diagram with standard maintenance procedures and ways to fix common issues that an owner may have.

I’ve been making good progress on the mower project and I thought it was time for an update. A motor mount was fabricated and sprocket attached to the steering wheel. Size #25 chain is being used to connect the geared motor to the steering sprocket. The motor mount is notched to allow the chain tension to be adjusted.

I also bought a linear actuator to control the brake/clutch mechanism. The linear actuator has a built-in potentiometer to provide feedback. This feedback will be used to set the end points for the actuator, so damage is not done to the brake pedal. The actuator has six inches of travel and 55 lbs of force for a margin of safety. As you can see, the mounting worked out well, as an existing hole was used and a threaded rod was run through that hole to mount the end of the actuator on a custom fabricated bracket.

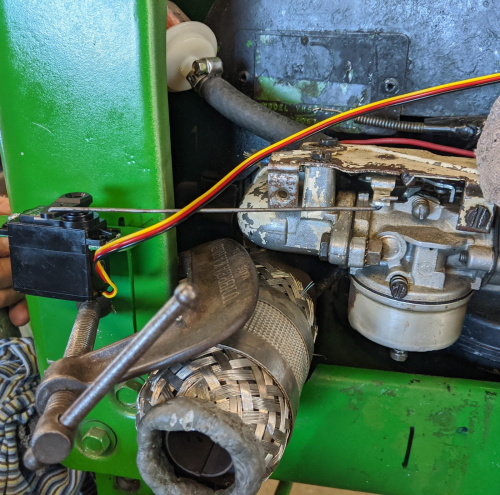

For the throttle, a servo was attached to the side of the tractor using a custom fabricated bracket. From the servo horn, a linkage was used to connect to the carburetor. This allows for full control of the throttle including the ability to kill the engine at very low throttle and choke for startup.

Another custom mount was fabricated to shift the mower between second gear, neutral and reverse. This completes the four major control systems required for the mower.

However, an extra safety system was added that allows the mower to be killed by shorting a wire that is part of the ignition system. This wire was routed up to the location where the controller will sit. The wire attaches to a relay on a normally closed connection. This means when the relay is not energized, the engine cannot run. This is a last line of safety in case the controller fails or power is lost.

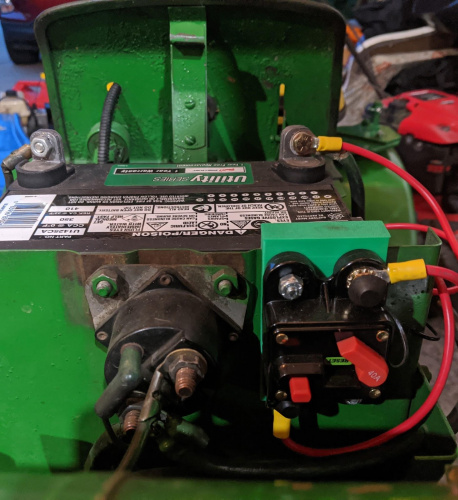

A new circuit breaker was added to power the new control systems and wires run to the location of the controller. A fuse block provides power to the various circuits, and switches are used so the controller can be powered but leaves the motors disabled for testing.

I decided to do some testing before all the systems were ready; here is the result of my testing late last fall.

The project sat over the winter, but I started again this spring. The various systems I described above were fabricated and tested manually without the controller. I then started to work on the code for the overall system. The system will have the following modes: INIT, START, STOP, RUNNING, FAILSAFE, MANUAL and KILL.

Here is a table with the various modes and sub-systems. Any software connected to hardware should have various MODES and some rigid guidelines to avoid any catastrophic issues. This is no time to slack on your code!

| Mode | Brake | Throttle | Shifter | Steering | Kill Relay |

| INIT | ENGAUGED | KILL | DISABLED | DISABLED | OFF |

| STOP | ENGAUGED | Idle | Allow Change | DISABLED | ON |

| RUNNING | Controlled | Controlled | CONSTANT | Controlled | ON |

| START | ENGAUGED | Controlled | DISABLED | DISABLED | ON |

| FAILSAFE | ENGAUGED | Idle | CONSTANT | DISABLED | ON |

| KILL | NA | KILL | NA | NA | OFF |

| Manual | Controlled | Controlled | Controlled | Controlled | ON/OFF |

The FAILSAFE and KILL modes are used if some failure occurs. Depending on the nature of the failure, a determination is made if it’s a FAILSAFE or KILL failure. Loss of radio contact is a FAILSAFE failure, but any communication failure with the controllers is a KILL failure. Other failure modes will be added as needed, such as low input voltage, temperature too high on some sub-system, over current on steering motor controller, etc.

I think most of these modes are easy to explain. MANUAL mode exists for testing, and will allow for testing in ways the other modes will not allow. My end customer for this mower will not have access to this mode.

From each of the above modes, only certain other modes can be intentionally reached except for KILL. Here is what switching to different modes looks like.

INIT -> STOP (Automatic)

STOP -> MANUAL/START/RUNNING

RUNNING -> STOP

MANUAL -> STOP

FAILSAFE -> STOP

KILL -> NONE

FAILSAFE mode is possible from any mode other than FAILSAFE or KILL, but the controller decides when it is activated. If the FAILSAFE condition is resolved, then switching to STOP is allowed.

At this point, all that is left is to test the above logic in standalone mode off the mower, and make 100 percent sure that the above logic table is followed and no crashes or weird behaviors occur. I’ve certainly found and fixed issues already, such as the brake not being engaged when switching from RUNNING to STOP. This would mean I could not stop the mower without switching to RUNNING mode again and that could lead to a runaway mower.

Once standalone mode is working, I will start testing the various control systems in isolation and then finally test the entire system on the mower. Please stay tuned for the final write-up on this project (hopefully in a month or two), and hear details about my next big project: a remote control/autonomous electric go-kart!

As a thank you for reading this far, I would like to let you know I have a special promo code you can use to get 10% off any SparkFun Original product. Just use ORIGINALRED2020 during checkout. This code is good through the end of 2020, but can only be used once per customer. Thanks for reading - I hope I can start attending STEM shows next year and show off my hard work on this and other projects I have been working on.

Project Submissions:

If you have a project that you want to show off and are interested in writing a post for SparkFun, tweet us @SparkFun, tag us on Instagram @SparkFun, or shoot us an email, but the best way is to submit your project by clicking the link below. We'd love to work with you and share your project!

This looks like a lot of fun. I would love to start a community around diy robot lawnmowers!

Here are some folks I have followed for awhile.

Good luck.

Per your request I started a google group

DIYMowers

I also purchased diymowers.com.

Please join. I'll reference that group in future articles about my mower. :)

Thanks for the links. If there isn't a community there certainly should be. I know of several projects myself.

Ardumower Valify-v2 Robo-mower

And many others. Certainly enough to support a group. I have a diyrovers group on google and we could setup something similar for mowers. If you are interested let me know how to get a hold of you and we can get it set up. :)

So far, so good! I do have a few thoughts to share, though:

It seems to me that "START" mode should require that the SHIFTER be in "NEUTRAL". (In my experience, many riding mowers have an interlock to require this.)

I can see some uses for the "MANUAL" mode even for the "end-user" -- for instance, trying to get the machine on or off a trailer. In most of these situations, it might be reasonable to have the engine turned off and the shifter in neutral (that is to say, user has to "push") and BRAKE and STEERING in "Controlled" mode.

Are you going to have some sort of sensor to determine whether the engine is running? (One way might be an accellerometer to sense the vibrations.)

And, conspicuous by its absence, is the mower deck... :-) ...a riding mower sans the deck isn't going to shorten the grass! There will need to be at least two more controls: a deck height control and a PTO engaged control. (I suppose you could rig a reel-type mower to be towed by the tractor...) BTW, I did go glance through the original post and saw that the "customer" didn't want to mow the grass with it, but I know I sure would! (Hmm... I've had a riding mower that had an electric blade engagement -- that would make things easier! Just need another linear actuator for the blade height control.)

You are correct about start mode. That was an over site on my part. I believe the mower will start in gear, with brake off but that's probably a very bad idea.

I am thinking about a move mode, that would work as you describe. Manual was going to allow some safety overrides for testing, so maybe I'll add a "MOVE/TRAILER" mode.

For this mower, no sensors are going to be used for monitoring the engine. This particular mower is just for RC, so I consider unnecessary. But on a fully autonomous mower certainly will at least consider it. I'll try to detect the engine rpm via a pickup, or just assume if I send a move command and the mower doesn't move that the engine is off? :)

Mower Deck. Down the road this certainly will be considered when I'm ready to create a fully autonomous mower or even fully remote control mower. I believe I will be using a zero turn, or other modern mower where the PTO en-gauge would just be a button. The deck height also will be considered at that time.

My focus once this mower done will be replicating this remote control setup on a go kart. Then I'll start on the autonomous work for the go kart and mower. I've got a lot of great parts for that, like the ZED-F9P GPS, Raspbery PI 4 (4GB) and RPLIDAR S1 . For the go kart I'll have a reduced number of controls, and the motor will be electric so that setup should be easy. Expect an article early fall on that. Thanks for the comments! :)

One change that would eliminate the need for a servo and gear shifter is use an electric generator to run an electric motor using a variable frequency drive. Plus it doubles as a portable power source. I've built one and have used it for over 10 years. It works great. I would post a photo but don't know if I can do it here.

Great idea. 😀 I'm going to build an electric go kart next and that will greatly simplify the control system.