In case you weren't aware, we ran a SPE Design Challenge where we gave out free hardware. We want to thank all of the participants who worked hard on their projects developing cutting-edge use cases for 10BASE-T1L SPE technology! With that said, here are the winning projects (WUU)! Drum roll please...

Category: Best Industrial Application

WINNER: LUMBERG AUTOMATION (BELDEN DEUTSCHLAND GMBH)

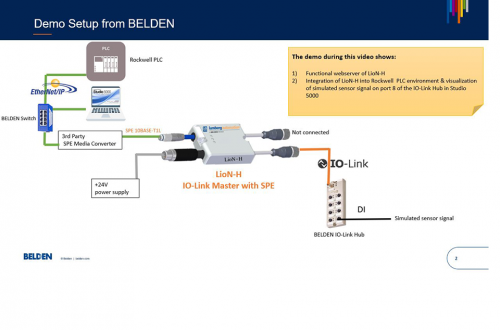

Project: IO-Link zu SPE 10BASE-T1L Gateway

The LioN-H is a Mini IO-Link Master with Single Pair Ethernet, supporting the 10BASE-T1L Standard for data transmission up to 1 kilometer. It’s a concept study which was made at BELDEN to show how to easily integrate standard I/O and IO-Link signals into an SPE network with EtherNet/IP. It has two cordsets for the connection of standard inputs and standard outputs or IO-Link signals. In addition, it has a power connection with an M12 L-coded cordset as well as an SPE uplink cordset for the connection to a switch or PLC.

Category: Most Sustainable Application

WINNER: MAGNETIC COMMUNICATION CORP.

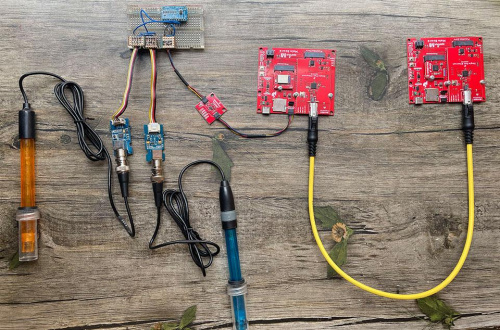

Project: Control system for farming via SPE

Magcom presents the closed-loop Single Pair Ethernet (SPE) system aimed at environmental conservation, harnessing the capabilities of SPE for long-distance data transmission, robust connectivity, and efficient energy usage.

Temperature and humidity data can be stored and managed locally and accessed on mobile devices. From a remote location, a mist diffuser (an example of cooler in the field) can be activated manually or automatically when the temperature exceeds a preset limit. This system enhances efficiency and facilitates data-driven decision making by not only monitoring, but also by taking immediate actions.

Based on this game changing technology, the system can be customized to suit various applications in fields such as medicine, infrastructure, plant engineering, surveillance systems, agriculture, wind energy and so on. Magcom leverages its Discrete Magnetic Technology (DMT®) to carry out your demands for increased automation efficiency and a more sustainable future.

Category: General

1ST PLACE: SCOTT RAPSON | ELECTRIC UI | ST. PETERS, SOUTH AUSTRALIA

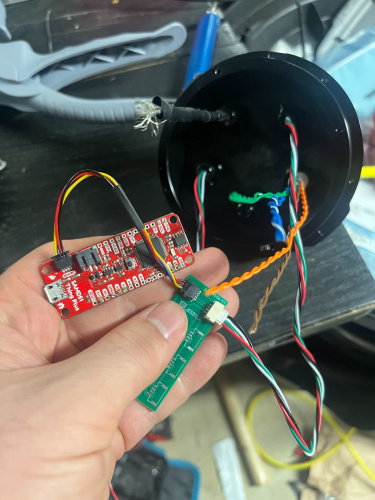

Project: Deep-sea sensor node / New PD and PSE function board

The project evaluated the practicality of using SPE as a single cable solution for marine research sensor node tethers by implementing a custom 10Base-T1L and Power Over Data Line (PoDL) board using the Sparkfun MicroMod form-factor. The SPE implementation was packaged with a 200m depth-rated enclosure with custom backplane PCB, 3D printed mounts, and an ESP32 to manage high-resolution pressure and temperature sensors.

To demonstrate the sensor node in the field, it was non-invasively mounted to a jetty next to a local dive reef and allowed real-time sensor review and recording at the surface.

Category: General

2ND PLACE: MD. KHAIRUL ALAM | DHAKAR, BANGLADESH

Project: Control system for drinking water tanks in residential buildings

All multi-storied buildings have one or more water tanks on the rooftop for distributing water on all floors. The main reservoir is placed in the ground and is usually filled by the utility supply. An electric pump pumps the water from the reservoir to the water tank on the rooftop. In most of the buildings in Bangladesh, the system is manual and a person manually turns off the pump when the water tank becomes full. This manual process always creates a waste of valuable water and indirectly creates a waste of electricity. An automatic system can solve the problem and save a large amount of water and electricity by automatically turning off the pump when the water tank becomes full and turning it on again when the tank needs to reload.

The project tries to solve the problem by an automatic system and the main problem was establishing a reliable communication between the water tank on the rooftop and the water pump on the ground. Finally, the problem was solved by Single-Pair Ethernet Communication. SPE can be the most suitable communication technique for communicating from rooftop to ground for a multistoried building, as single-pair ethernet can reliably work for more than 1 km. For turning the pump ON and OFF at the right time, sensing the water level at the tank is required. For sensing the water level, a TOF distance sensor is used. A PH sensor and ORP sensor for measuring the water quality with the level sensing is also added.

This can be an economic and reliable solution for household water pump control. Implementing this system can save a large amount of water from waste. Remote monitoring of water quality is also possible and it gives an important clue when to clean the water tank.

Category: General

3RD PLACE: JULIAN BLANCO |NORTH STONINGTON, CT, UNITED STATES

Project: Acoustic Monitoring Buoy

The goal of this project is do basic underwater acoustic monitoring. The bottom unit consists of 4 hydrophones, a temperature sensor, depth sensor, an acoustic data acquisition system from Applied Ocean Sciences, and a Single Pair Ethernet transceiver. Messages from the bottom unit will be transmitted up the tether to a surface buoy where a radio (cell or xbee TBD) can pass the message to shore.

Do you have a super cool project you want to share with us? Shoot us a tweet @sparkfun, or let us know on Instagram, Facebook or LinkedIn. Thanks for reading!