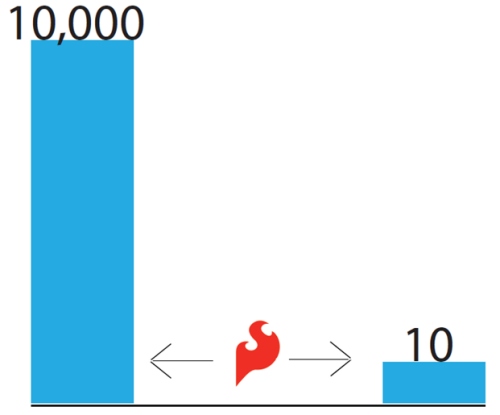

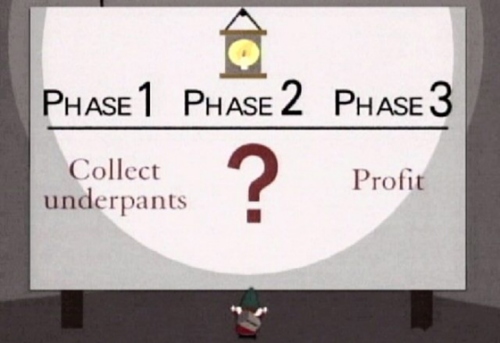

The number of businesses selling very cool electronic bits (and every handmade item for that matter) has exploded over the past few years. It's been really exciting to see all the new products hit the market, but what surprised me was the reoccurring challenges those companies face. We've seen these new products fall into three "buckets": the happy bucket, the work bucket, and the pit of despair. I presented the concept of the pit of despair at the Hardware Innovation Workshop. You can see the video over here, and you can get a PDF of the presentation here.

A portion of products and projects fall into the first bucket. I call this the happy bucket. These products sell a few per week and the creator can fulfill the orders that come in over the web while keeping their day job. Maybe it's a messenger bag made from recycled bike tubes, or a laser cut kids' toy. If they can make enough extra money to buy some new tools, they consider it a win. These folks really enjoy making things and the reward that comes with them.

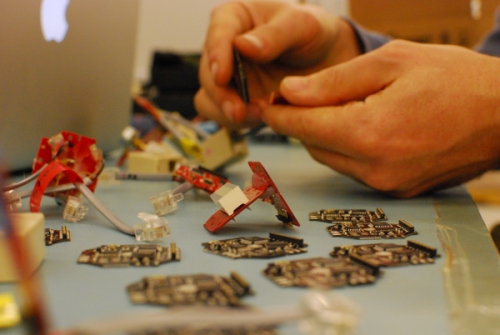

Massive assembly

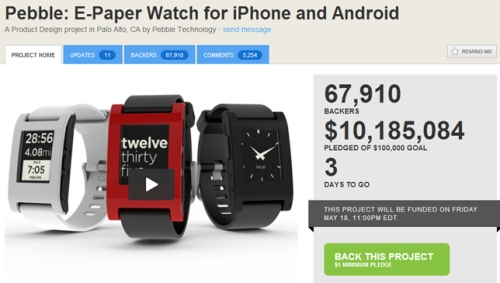

A very, very small portion fall into the second bucket -- the work bucket. These products have enough wild demand that it makes financial and mental sense to quit the day job and concentrate on building this product. Like I said, very few projects have this clear a delineation.

Painful assembly: From Nonolith Labs - “This is what you'll get. It took us about six minutes to test/cal, screw, and kit this. We just have... 150 to go...”

A surprising amount of products fall into the third bucket. I call this bucket the pit of despair. These products get far more attention than the creator(s) expected. The product was well-designed but may have been designed for kitchen production, where they planned to build tens of units. When demand grows beyond thousands, the creators are often forced to make tough decisions: the income may not be enough to release them from their day job, and the amount of time required to build the product begins to gobble up evenings and entire weekends. If you've ever had to count out 150 bags of resistors and LEDs, you know what I'm talking about. It's really painful.

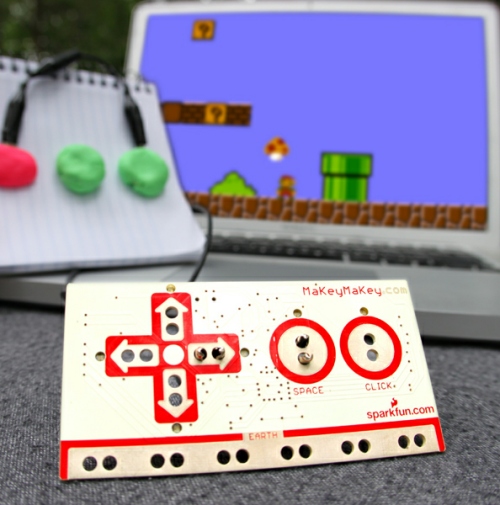

We've even brought some pain on ourselves with MaKey MaKey. We figured 300 units would be a win, 500 would be a slam dunk. We are currently building 13,000 units without too much handwringing, but it's not something we're used to seeing.

It's at this point, when folks are thrust unceremoniously from tens of units to thousands of units, when they contact us to collaborate. We've seen an explosion recently with the popularity of KickStarter to raise funds and get pre-orders.

We love having the opportunity to work with folks to bring their ideas to life. It's always fun, but collaborations are really challenging. An idea is a great place to start, but there are a tremendous number of details that can cause the project to fold long before it sees e-commerce goodness. Questions like:

- Does it work?

- How big is the market?

- Can it be made for a reasonable amount?

- Can it be priced at a level that makes sense?

- How much support will it need?

- Does it need regulatory testing or approval?

- What changes need to be made for international customers?

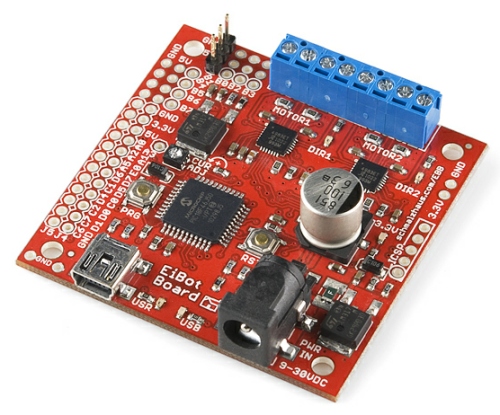

EiBotBoard was a phenomenal three-way collaboration between Brian Schmalz and Evil Mad Science Labs.

We've had a handful of successful collaborations, and equal number of unsuccessful collaborations. There is, however, a much larger heap of projects we just couldn't take on. As funding sources like KickStarter, IndieGogo, and RocketHub grow, the challenge only increases.

While we are trying at the moment, I don't believe SparkFun is the answer to the pit of despair. We have to pass on far too many projects. There needs to be more of a free market for ideas and products. This is a tough nut to crack; I would love to see a peer-to-peer site or community service that addresses:

- Funding : KickStarter is good for donation-based funding, but what we really need is crowd investment. You should be able to invest in a project rather than simply pre-order.

- Marketplace : Anyone who has put together a KickStarter or e-commerce website knows it's a lot of work to put together a winning product. There needs to be a common place, owned by no one, where folks can go to discover new and potential products. SparkFun is not in this business and doesn't want to be. Because of an inherent conflict of interest, I don't believe a marketplace can be serviced by companies that sell things (Adafruit, MakerShed, O'Reilly, etc.) -- we just get in the way! Seeed Studio has made a pretty good try at this, but is lacking key pieces.

- Community Help : It's tremendously hard to pull off the production of a given product. Collaborations help, but don't fill the entire gap. We need a community to share all their "gotcha" and "this is how I did it" moments. A good example is injection molding knowledge -- we've learned a lot of lessons at SparkFun and try to share as much as possible. Imagine if we could get Tod Kurt (checkout his kickstarter!), Kipp Bradford, Mitch Altman, and Liam Casey to tell us what to watch out for? We need a good system (forum, FAQ, knowledge DB, etc.) to congregrate all the group intelligence in a useful way.

- Design for unorthodox-manufacturing (DFUM) : Because of the size of the pit of despair (hundreds to thousands of units), normal manufacturing (hundreds of thousands of units) doesn't directly apply. We've figured out how to manufacture short-run, high-mix products, but the vast majority of products that are proposed were not designed to take this into account. This site or community service needs to help guide creators to alter their designs so that the product can leap from the kitchen table-scale kitting to slightly higher garage manufacturing.

- Crowd-sourced assembly : SparkFun recently had a soldering contest where we invited local hobbyists to show up and throw down. Much to our surprise, the professionals showed up. Even in our neck of the woods (Boulder, Colorado) there is a surprising amount of talent and available production capacity. I am not talking about contract manufacturers (CMs). The products that fall into the 'pit of despair' are too small in volume, so the economics of CMs don't work. Instead, I believe this site or community service could link all sorts of people together. There are folks that have free hours and the ability to kit or reflow SMD boards in their home (yes, you can too); why not leverage all the available hackerspaces, kids with free time, or adults looking for work?

As I said, this is a tough nut to crack, and we're not the ones to crack it (our job is to build shortcuts). So if you've got some free time, could you just whip this up for us? It would significantly ease the problems that small- to medium-sized innovators are running up against. It's going to take the long tail of products to a place where we all get what we want. Who doesn't want that?

I would just love to be a part of crowd-sourced assembly! It would be a great way for me (a fourteen year old) to make some cash to buy parts.

I'm in the exact same boat as you. I enjoy soldering kits together more than playing with them! I recently got an SMT Blinky POV from Makerfaire and pretended to do my actual homework as I soldered it together.

Re: "KickStarter is good for donation-based funding, but what we really need is crowd investment. You should be able to invest in a project rather than simply pre-order."

There are platforms that do this, but not very many based in the U.S. You run into all sorts of regulations, SEC filings, etc. that make that a hassle. The JOBS Act aims to make all that a lot easier while at the same time covering regulation of some existing platforms (such as KickStarter).

I'd argue that while KickStarter projects may seem like either donations (throw money at it and don't expect anything in return, even if the project description says you should be getting some 'thing') or presales (Pebble, OUYA, etc.), a part of it can be seen as investment; you just won't get any shares, equity, etc. But you do get to be part of a product's development and, with any luck, its continuing existence and building of an ecosystem around it.

With the OUYA, for example, there are plenty of other (more or less) open gaming platforms - but they don't really have an enthusiastic customer base that reaches critical mass for them to break through. They're fun to tinker with if you're into that sort of thing, but it's not generally something you'd recommend to any random person. Even when the device itself is popular enough, if there's barely any support for it as an open system, it's semi-pointless (OpenOS on PS - lots of outrage from it being taken away, but the number and quality of indie projects available for it was disappointing at best). OUYA has already reached a critical following. Even if OUYA itself may fail (perhaps due to patent litigation, if any of the existing console manufacturers and others want to go down that road), it might have opened up the door just wide enough for others with greater potential to try and wedge their way through. That in itself is a 'return', even if it won't do anything (directly) to help secure your retirement plans.

I agree there's a wicked thicket of regulations in the US and that JOBS did a questionable net positive to getting us there, but what I'm arguing is that too many people believe KickStarter to be the answer to funding when it's not funding at all - it's preordering. And that can be a good thing for most projects but I believe there are some larger ventures that need to be tackled (biomedical sensor development, alternative energy, I'm brain storming here) that will need much greater levels of funding and those backers will require something more than a t-shirt. We (in the US) need a system to micro-invest, I'm just trying to speak up.

OUYA - whoa! I had not seen that one. You make a good point that KS can be used to pry open markets that would normally be very hard to crack. The console market is very hard indeed. But that might be too far up the popularity chain already. If 31,000 people are backing it (at the moment) that's already pretty popular. They have all the momentum they need to go to mass production with today's tools. I'm hoping someone creates a way to buy/sell/build 6 of something, and make the process and businesses sustainable.

'it's preordering' -- Great point, Nate. I've watched several makers launch KS campaigns to fund their projects. The "successful" ones I've met are all stuck in the pit of despair as they struggle for months filling preorders. One guy raised nearly $1MM and still doesn't have a clue what a purchase order is.

A new funding platform is a fantastic idea, but production is only part of the problem in these pits of despair. We also need to development a new opensource platform (or at least resources) to assist makers with the overwhelming tasks of accounting, database development, and shipping automation that start-ups inevitably face. I'm thinking something like Oracle, but opensource.

Thanks for sharing! That was painful to look at.... Hopefully anyone who supported this project will get a nice board soon.

Jesus... those pictures were awful but seeing the other pictures in the thread... those poor pcbs and components will never work the man is using FREAKING HUGE amounts of solder paste, in some pictures you can see mounting holes filled with the stuff, people have been posting videos of "proper" home smd re-flowing but the man just keeps using more paste on a component than I have spent on a small production batch and that is not an exaggeration of you see the pics. Best luck to the ones who spent money on the kickstarter, at least the guy still hasn't given-up.

Well, what I'm arguing is that it really depends on the project whether you're funding something, pre-ordering, donating, investing (with no immediate monetary return), etc.

You're right that KickStarter is certainly not the be all end all - if it were, there wouldn't be an IndieGoGo (accepts business funding, small causes, fund-my-life projects, etc.) or Causes (large causes) or, indeed, the platforms where you can indeed invest (as in getting a 'share' of the company in one way or another, with monetary returns if it makes enough profit/etc.).

It would be nice if such a platform were readily accessible to smaller developers (such as those that approach SparkFun with some frequency, no doubt), and hopefully we'll see these popping up as the JOBS act and various legislative measures settle down.

OUYA is definitely on a different level than what you're suggesting. For very low volumes I think logistics and availability of appropriate 'makers' tends to be largely the enemy. It's definitely a tough nut to crack on that front alone without getting into various of the other desires; but dreaming big is good, it can get the ball rolling. I would guess the first step would be a registry of talents (more specifically, manufacturing capabilities.. i.e. for electronics can etch boards? 2 sided? has access to components?) that can then be put in touch with project creators - I just fear that it would quickly devolve into a lowest-bidder marketplace.

It seems like one of the biggest mistakes entrepreneurs make is to assume that their labor is free or at least forget to account for it. Pricing that expense correctly makes possible both transitioning that task and scaling the production capacity.

Choose a reasonable hourly pay rate and figure out how many boards per hour an experienced and competent assembler can produce. Divide the hourly rate by the expected number of boards and that's your labor cost per board.

Like labor, errors are an expense that needs to be accounted for or mitigated somehow. Crowd-sourced or flash mob assembly just seems ripe for QA issues. I guess one way to make it work would be to sell the parts (at cost) to the assembler and pay them for every board that passes QA (labor+parts).

Crowd-sourced assembly might not be compatible with the various regulatory and certification regimes. That might even require each assembler to hold their own certifications (which will increase the pay they can demand).

QA is a worry but I feel like this could be fixed with a good document that is created along with the product. We have to create a test procedure and design a test jig at the same time the product is designed (you can't think about QA after you've designed the product). This goes for any type of product (a soccer ball). Once the level of expectations are set (no you cannot deliver a soccer ball with two white squares next to each other) I bet a feedback/review system would do wonders. Expert assemblers with better reviews and more experience would net a higher rate. ODesk is a good example of this.

Seems there is a need for a clearing house for skilled hardware manufacturing labor. Like what Odesk does for software or taskrabbit does in general. A place where subcontractors and the folks hiring them can rate each other like eBay does for buyers and sellers. Ratings for work quality, skills, turnaround time, reliability...

Fantastic article. The timing coincides with recent thinking about how I (and others like me) might get our little circuit board (or whatever) inventions out there, visible, available. Many hobbyist electronics blogs have shops tied to them. I wonder how much they sell.

They might sell more (and folks would more easily discover cool things) if they outsource to an aggregated storefront like an Esty/Amazon maship (tindie.com anyone?). But that's not all, definitely I've thought of outsourced pcb fab & assembly. Then there's the hassle of shipping, too. Hm.

Thanks for mentioning lots of things to consider that never even crossed my mind. "Could you just whip this up for us?" Ok, yeah, let me get started. Probably can get that together by next Friday or so... who's with me? :)

tindie.com - Another one I had no idea about. Thanks! That looks like a great place to sell a widget. Here's a great example of a product that, for sake of argument, 10 people need. If the creator can build it, it works. But imagine if I could sign up as an assembler and help GeoNomad help build her/his product for a wage? Could be really good for GeoNomad when they need 100 units instead of 10.

What I'd love to see is the short run Pick-n-Place business. Something like BatchPCB or Seeedstudio but for using a PnP. They post standard tooling sizes (like standard board sizes they can run easily, maybe some jigs for other sizes) and reel sizes. I send them a stack of boards and a bunch of labeled reels and they load it up on the PnP and place everything.

You know Nate, I've crossed the Pit of Despair on two separate occasions with the help of Sparkfun. I'm sure you guys realize that an order of 200 widgets ain't exactly tinkering, and I've built your lovely goods into short run, quick turnaround products.

Real Pit-swinging takes a very particular variety of DFA- minimizing joints over all other parameters. Every solder joint increases the assembly time and provides more opportunities for failure. It's also helpful to live near a university as a source of cheap soldering labor. Hiring students is far smarter than imposing on your friends, especially when you're making a profit.

Thanks for all the support over the years!

Some recommendations that may help to avoid the pit of despair:

Find out in advance as much as possible how to produce your item, and outsource as much as you can. Take the costs into account. If you need to assemble some parts yourself, figure out the time, and "pay" yourself adequately when you calculate the retail price.

Test your design, have a prototype that is identical to the product you want to ship, before taking people's money. Takes a bit of commitment, some of your own money, and a lot of time, but you'll sleep better...

There are actually a number of companies now that are specialised to small runs at affordable cost:

Shapeways: upload your 3D design, market it, profit. They take care of everything - customer service, financials, production, shipping, etc. - and you'll get your markup paid every month. You can use their web-shop facilities, so you don't even need your own website/ordering system/payment system, etc. As long as your design can be 3D printed without any extra steps you only have to design, and make sure your design works. No need for pre-orders either, as long as you can afford printing your prototypes for testing.

Ponoko: Similar to Shapeways. They do laser cutting and 3D printing, and also distribute Sparkfun goods. Main issue with combining electronics and mechanical parts here is that your customers will have to assemble it themselves, and there is no provision for custom electronics, or a finished, assembled product. You can do those steps yourself, but then you have to handle sales yourself as well (don't underestimate sales and order fulfilment!)

PCB-Pool.com, pcb-factory.de (Germany only), etc. PCB manufacturers (similar to BatchPCB), but they also do board assembly for any batch size (gets cheaper per board for larger batches of course). They order the parts for you as well, you get finished PCBs. For a batch of 50, the whole manufacturing and assembly cost might be under $10 depending on your design, plus component costs. I just realised that PCB-Pool does offer assembly on their german website, but not the US... Maybe BatchPCB could offer this as well? Or do people know alternatives in the US?

Protomold. They do injection molding, starting at around $1500 tooling costs. For 1-50 units, 3D printing is probably better if the quality is sufficient, for larger batches this can be the way to go.

emachineshop. A bit more pricey, but they do all sorts of machining. Their software gives you instant quotes as well.

In summary, if you can adapt your design that production is almost completely handled by companies like these, you either have no production work yourself, or only some simple final assembly tasks. With this new breed of digital manufacturing tooling costs are nonexistent or at least quite low, so you can actually go from 1 prototype to 100's or 1000's of units without too much pain. Unfortunately it doesn't work for all projects, but if it does it's great.

In regards to crowd-sourced assembly my wife sewed soda pop can sleeves on an industrial sewing machine down in the basement and she did some other piece work to help with the family budget. That was about twenty years ago. I haven't known anyone personally who does that anymore. It seems with today people needing extra income every little bit helps. So why not take advantage of a great local work force. Thanks for bringing the idea to mind.

Interesting article. I can definitely understand the need for such a place. I'm an amateur hobbyist when it comes to gadget tinkering, but I have had an idea rolling around in the back of my head for a project that I know could make work, and think it would have a fairly descent market, but haven't really put much effort into it because I don't want to get stuck in the pit of despair with it :)

That said, main reason I'm commenting, I do have the technical know how to create a web site like this, but I don't know what all features would need to be on it for something like this. The scope of the project also sounds like it'd be close to throwing the developer of such a website into a pit of despair themselves lol. Large scale websites aren't exactly cheap, there are hosting / server fees and a lot of man hours involved in the coding. I'm sure this would require a lot of custom coding, so just slapping a template together wouldn't exactly work. A site like this would be potential high traffic, so you are probably going to want at least one descent sized dedicated server to begin with, and if it gets really popular you may have to get multiple servers to handle the load. You might could get started on a small virtual server, but then it is likely to suffer growing pains as popularity gains (outages and such).

I know you mentioned a place owned by no one, but realistically whoever would be running and managing such a web presence would need some sort of income on it to make it reasonable. Once it's up and running it could probably be maintained in spare time, but the hosting costs are recurring perpetually, plus server upgrades / maintenance, etc.

All that said, I might would be interested in taking (or working with people) on such a project, but I would need people working with me that have a good idea on what all features it would need, and what some of the regulatory hurdles would be, pretty much anything that doesn't deal with the actual coding :)

Great writeup, Nate. I've been in the Pit of Despair for a while now, and have felt very guilty about being grumpy and tired when I feel I should be enjoying the success. I'm glad to hear I'm not alone. Can't quit my day job, but don't necessarily want to work every night/weekend either. It's hard to relax because there's no such thing as "done".

A bit late to the party.

In response to "Seeed Studio has made a pretty good try at this, but is lacking key pieces." What do you think those key pieces are?

Also, when I do figure out how to manufacture, market, and sell my widget where in the h e double hockey sticks can I find the right sized box?

"We need a good system (forum, FAQ, knowledge DB, etc.) to congregrate all the group intelligence in a useful way."

Please please please please please!

Not a forum. Not an FAQ. The world needs a collaborative design website. You post your project idea and then ask for help from people with different qualifications. "Project title: I have this idea for a project and I've designed all the electronics, but I need help from a mechanical engineer". Each project has a wiki/discussion board for planning and exchanging ideas. Schematics, blueprints, mechanical drawings can be drawn and edited directly on the site like circuitlab.com or upverter.com. Maybe a graphical roadmap planning tool. Everything collected together in a repository revision control system so you can see who made what changes to the schematic and fork a project to create your own related project. all the files open source (or private for pay, like github)

There are lots of tools for collaborative design of software, but none that I know of for hardware. Whoever makes one please let me know. :D

Content to be at the "happy bucket" point now (http://cal-eng.com), but this article touches on two different paradigms; one being the incremental business growth, the other the weird quasi-random Kickstarter success (or lack thereof).

My plan and execution so far has been quite deliberate (and fairly slow), here's a few observations:

Why do you want to do it?

-- Money? Stop now, rethink your plan, and get a real job first!

-- Because you love to design? Good! That's critical if you want to sustain momentum.

How will you do it?

-- Get a second mortgage and quit your day job? Nope, -really- bad idea!

-- Spend a bit out of pocket and build on-demand? Yup, in the early going, minimize all costs where practical.

Where to start?

-- Design, but try to add value somehow. You simply can't compete with China building existing open source designs.

-- IP (particularly trademarks) are critical if you intend on growing an on-line business. You domain name is absolutely everything, don't leave it 'till it's too late, also be prepared for challenges (been there, done that!), and if forced, a complete re-naming of your venture might be needed, right off the bat!

-- Keep inventories to a bare minimum, and buy commonly-used components outside of normal channels at huge discounts. If you have a way to cut PCB's, ganging distinct circuits on one PBC cuts per-units costs dramatically, particularly for prototype development. (you WILL make PCB design mistakes!) Finished product inventory is a really bad thing, unless you are incredibly confident about future sales, and that assumes that you're happy with the design as it is.

How to grow?

-- Patience, young Jedi, a site that offers lots of good information and compelling products will slowly gain momentum on it's own. (nowhere near there with my site yet!)

-- Don't sit on a small handful of products. Keep innovating, even if it means forcing some of your existing designs into obsolescence. PCB's are stupid-cheap, don't get obsessive about the need to sell all your existing stock of one particular design.

-- Did I mention a robust site? ;) You want your site to be a destination of information and learning, with the added bonus of cool stuff to buy! Sparkfun and others excel at this, and it will pay in spades since a happy maker is a buying maker!

What's the end-game?

-- This is a tough one. Do you -want- to be another Sparkfun/Adafruit with million-dollar+ revenues, a large, staff and essentially become a "businessman"? Personally, not really...

-- Would you like your passion for design to pay the bills, or -perhaps- replace your income? A worthwhile goal, and as long as you keep fresh and offer value, probably not too hard to attain after a few years (3-5?).

-- Don't forget to incorporate and keep precise records, since someday you might want to sell your venture. A small web-based business is incredibly easy to sell since inventories will be minimal, there will be no property or (hopefully) liabilities involved, and the value lies in goodwill and proven revenues.

Well, those are some thoughts from a 6-month veteran of the on-line world! It's been fun so far, and with very modest expectations in-hand, looks like it will continue to be fun & challenging!

I am starting on this journey, don't know which "bucket" I will end up. Probably the 4th bucket which Nate forgot to mention, that is "Crash & burn". :-)

I am working on project to build low cost vision module, here is the sparkfun thread http://forum.sparkfun.com/viewtopic.php?f=14&t=32645

This my 3rd attempt at making a widget. What I have found out so far is that you have to spend as much time on marketing and selling your idea as you spend on the technical stuff. This time I am giving more attention to selling the idea than I did before. Hopefully this time it won't be "crush and burn" bucket.

Cheers

I'm in a similar situation. I have several products that I would have no problems selling, but I have to keep the quantity down to avoid the pit of despair. That pit is huge - the gap between the happy bucket and the work bucket is just too big of a leap. I can't taper down my day job to build up my product sales, it's all or nothing. If only I could find a turnkey assembler similar to something like BatchPCB, that I could send my files to and get assembled PCBs for quantities between 50 and 1000, at a reasonable (profitable) price. I'll watch here to see if anyone knows of such a thing.

I've worked with Gold Phoenix (http://www.goldphoenixpcb.com) for quantities of 100-500. They manufacture, test, and assemble PCBs, and their prices are excellent. You send them design files and components. Lead time can end up being a month total due to things getting hung up in customs for several weeks if you're shipping from the US, especially if certain components are involved. But overall, I had a good experience and ended up with quality units.

Thanks, I'll check it out.

I was so excited about KickStarter, now I am learning a new level of patience and understanding and compassion about the Pit of Despair. Backer updates and communications are HUGE to me. Thanks for letting me know about your frustrations with China delivery times being lost in translation, Thanks for sharing your google docs reward fulfillment worksheet. Thanks for sharing your progress.

The problem, at least with me, is that as a consumer, I have become spoiled. I know that my order confirmation email will hit my inbox the second I place my order. I'll get a tracking number I can put in my phone to wake me up at 2am to tell me that my SparkFun package just arrived at the UPS facility in Ontario, CA. I will expect my wonderful red box to be sitting on my desk by the time I come back from lunch. Knowing that that night solder will flow and magic will happen.

Very cool article and perspective.

I'm coming at it from a similar... but altogether different direction.

I am working to develop a commercial product line for a niche market. I'm not trying to cater to the hacker community, the prosumer, or even the general consumer at large... but I still face these hurdles with manufacturing. I can easily prototype in my kitchen (to my wife's horror)... but I can't produce 1000 units there (or even store them!).

Does anyone have any ideas for a fledgling business feeling this same issue?

And oh, I am going through http://www.Invested.In for my crowd funding attempt. It's so hard to fire up an actual business and get investors when you are dealing with such small (but lucrative) market!

IMO your best bet (especially in the lowish quantity commercial or prosumer markets) is to:

1) Price your widget right, meaning properly account for all costs and the amount of profit you need to make to consider your endeavor successful. Don't forget things like test, packaging, shipping parts, taxes, business fees, etc. If what you're selling really doesn't exist, you can probably price it higher than you think.

2) Find a reputable contract manufacturer to work with on manufacturing, testing, and potentially even packaging and shipping your widget.

3) Have reserve funding to fill gaps of time by expediting if necessary to deliver products and create happy customers.

4) Do everything you can to test well and minimize support, but don't forget about support costs in your pricing scheme.

As someone that has done this on a smallish scale with descent success (I can ship 50-100 units per month, all I have to invest is 1-2 minutes per unit for test and packaging at this point). I build to expected demand, and balance cost with price such that I can build in batches that minimize my risk and maximize profits (I find this to be around 200-300 units for my cost/price point (around $50 unit cost for parts+assembly+test+package, $100 price). I put my first profits back into the business, so that I'm now playing with 'business money' and no longer investing personally. I'll ride the train as long as it lasts and then come up with another widget to sell when it starts slowing down.

Nate you hit the nail on the head. We feel the Pit of Despair often as we are a small company and our PodBreakout board is very popular. We are in this position where we are small and can produce large quantities, however when we get very large orders it can seem daunting. Most of our products are assembled by hand.

Nate, fantastic article and I agree with every point you make.

One thing to consider is, governance of this hackimmunity (hacker+community, I know it doesn't sound right, I'm an engineer not marketing). Combining features of Kickstarter, distributed work, and "store front" all need to be regulated in some fashion. Yes government has a lot of oversight on trade and IP (especially to foreign countries), someone or a group of people need to fill this paperwork out.

So we got all of these features for this hackimmunity, A fund raising point, a marketplace, community driven based upon skills, DFUM, and assembly. How are people going to coordinate? An inventor/creator can't really do all the planning for each step without running into time concerns (or even proper documentation. IE: how to assemble, test, etc). For example, let's say I make a widget that I designed for myself, but enough people caused interest to explode. I don't want to lose my day job (the project could blow up in my face). There needs to be some kind of regulatory group whose job is to handle government paperwork, try to make the process painless for inventors/creators, and coordinate work among the community... To me, this sounds a lot like the Linux Kernel type hierarchy system (minus the big figure head).

I know a lot of people are against any type of governance in Open Source or community driven systems, but there's no way around it. You'll end up having something like Lost.

What are people's thoughts on this?

The best way to introduce regulation to a movement like this is to induce self-governance by incentive. Start, or encourage others to start, businesses that provide the logistical services you're talking about for inventors/makers/"The Little Guys" by forming partnerships with manufacturers, funding sources, retailers, etc. that are mutually beneficial. Then, charge a reasonable fee for makers to use your service. You never handle the product, you just coordinate it's progression through your partner services and become a centralized hub for the product history and paperwork. If the paperwork is as much of a sticking point as you posit, then the market will support inventors who use your service and those like it, causing a natural progression to the standard you set for documentation and licensing.

...you could Kickstart it.

EDIT: I said "best way," I meant the best way that comes to mind for me.

Also, I suspect that these businesses would be 'of' the maker community and I would encourage them to develop OS (Free Software?) tools for this kind of logistics/process management challenge, encouraging others to form similar firms and giving back to the OS/OSHW community.

Great Article. So I'd argue the tangential; that what is needed to extend the long tail is a physical specification for I2c which does for small PCB's what USB has done for computers. All of the items pictured above, and a million more like them, are little more than a microchip connected to one or more sensors/motor drivers, and since almost every sensor or driver is available in an I2c version, the only reason to design and solder a dedicated board is due largely to the lack of sufficient adoption of an I2c phy spec: Want to build a reprap? you need 1 Teensy, 4 I2c Servo Drivers, 2 I2c Temp probes, and a 2 Channel I2c MosFet Board. Change that to an QuadCopter - you need an I2c GPS, I2C Servo interface, and an 12c gyro/accel.

If the cost, weight, and size of the connection were small and getting smaller - like USB has done; these modular boards would be less expensive in these quantities than manual fabrication; and the number of custom configurations would be staggering.

Ohhh - don't get me started about universal protocols or universal connectors ;) I've got an entire rant written about that. But for now, I'll just leave this here.

Thanks for the article, Nate. I agree with you and Kevin. I too have searched for and tried to define the holy grail of a universal hardware interconnect. SPI and I2C are appealing for this since so many chips use them. But when I built real systems with I2C and SPI I learned a few things, mostly the hard way. These interconnects are intended for chips on the same board and with a very good ground interconnect. When run through wires, they radiate and pick up EMI and noise by causing high speed return currents to flow in the grounds. When static (ESD) strikes, you can get errors, also induced across the grounds. And since SPI and I2C have no error detection or correction, you are in trouble when an error occurs. Controlling high current loads (without isolation) can also cause EMI and bit errors.

Another downside of I2C: the rise-time and thus bus speed is a function of the capacitive loading which is a function of the accumulated wire and PCB trace lengths and the number of loads. Many larger I2C systems need to be tuned to get the pull-up resistors right.

For system-level interconnect in large systems, CAN is often used. CAN is differential so it generates far less and is far more immune to EMI. It is impedance controlled so it can use long wires. It has built in error detection and correction. It has built in addressing and slave response prioritization but without the time uncertainty of multiple-retries. 1 megabit per second is typical. I think there are standard CAN connectors, not sure though. The downside of CAN is that peripheral chips don't talk CAN. Each peripheral pretty much requires a microprocessor and CAN driver, adding a few $$ and some development time to each node.

Thanks, Dave

You wrote since almost every sensor or driver is available in an I2c version, the only reason to design and solder a dedicated board is due largely to the lack of sufficient adoption of an I2c phy spec. I understand your idea, but I think your reasoning is insufficient. There are physical reasons why i2c cannot be used (too fast, simultaneous access needs, power requirements), historical reasons (UARTs, for example, are the old standard for some areas), and mental reasons (more familiar with another protocol, NIH syndrome, etc.). Every protocol has its merits and demerits. However, no protocol has all the merits and none of the demerits.

I see you're a fan of i2c/SMBus/TWI. That's a great protocol, with the following advantages:

However, it has a few disadvantages.

You can argue that it's the best compromise for your purposes, but it's unlikely that as long as engineers are choosing the best spec for their individual purpose (which will save money when produced in large quantities) that this will ever see the mass adoption of USB.