SparkFun is not shipping out any orders on Friday, November 4th. This is because we are counting our entire inventory that day. Our apologies for the inconvenience.

It's not AVC, or Open House, or a Viking Funeral, but SparkFun has one last event this year: Inventory Day. Like any company dealing in physical goods, at least once a year we get to prove that we actually have what inventory amounts we think we have.

For us, this proving is done by taking a physical inventory count annually. While we are looking at other methods to avoid the kind of event planning and disruption that we are going to experience this weekend, we're not there yet.

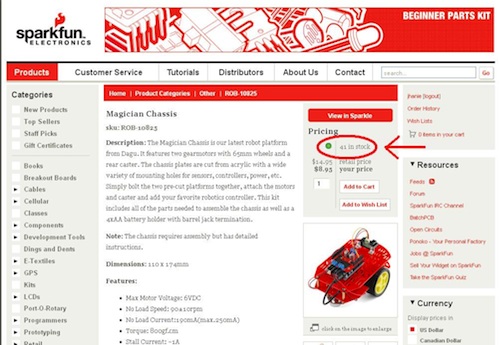

What a physical count entails for us these days, is orchestrating all 135 employees to count all the units of each of our 2028 products for sale to you, our customer, plus the 1533 we have on hand to build with. We'll be going through the shelves, one by one, and comparing the counts with the quantities we think we have. If the match isn't sufficiently close, we get to count again to make sure we weren't mistaken the first time. On some products we will be writing off the lost amount. On others, we'll find a quantity that ended up somewhere in the warehouse that it shouldn't have been.

So, please forgive us, and enjoy the new products post on Friday, knowing that your items will ship just a touch later than they would normally.

How about guessing how many items are missing, and the closest one wins $1 per item :p

Embrace the cycle count. Back in a previous life I was a warehouse manager. We would randomly count areas of the warehouse to confirm the numbers. Or we would designate someone that every time they went to fill an order they would count the inventory of the item they are picking. You can't have everyone counting everything constantly or you would never fill enough orders. I was lucky in the fact that everything in my warehouse wasn't tiny.

There is nothing a warehouse manager loves more than the picker to come back and say "It says we have 3 but there aren't any on the shelf".

I get upset just thinking about it.

One, Two, Three.... Looks like one hundred to me!

RHYME ACTION GET!!!

Is there someone in charge of counting the inventory of all those red boxes?

It's actually pretty difficult. There's too many thousands of boxes for even multiple people counting so I think they're resorting to volume and weight calculations. Not sure. It's mind blowing the amount of work it takes to get this building fully counted.

During our tour a couple Fridays back, they said every single employee pitches in. It's the only way to quickly knock out this IRS requirement...

worked for a international tool distribution company used bar codes and portable hand scanners to scan items, worked perfectly.

Invert the problem!

Don't count what you have, count what you do not have.

Let me explain that in a more rational sounding manner... Let's call it buffer-assisted cycle counting, or some such fancy buzzword. Whenever an item is close to it's count date, start putting fresh stock aside (or just divide it's shelf with a marker). Whenever the old pile reaches zero, confirm you have zero on the shelf, adjust if there's more than expected, and toss the marker. If your physical inventory runs out before expected, adjust then, and toss the marker.

No more counting, and accurate results.

(okay, you might want to run over the new stock with a bardcode scanner when tossing the marker, but you should never have to count items, just boxes, and only for a single item-type at a time)

Sounds good?

(simply put: cycle counting weighted by when old inventory is or should be zero. Or just take inventory count modulo box-size, and count when it's zero, and you only should have full boxes. For loose stuff around production etc, run the box-count when you're out, and need to get more (whole boxes) anyway).

(cycle-counting seems IRS-safe, this is just smart-weighting it, and should be fine)

That sounds like a pretty good idea to me! Maybe it would be easier to have boxes of "new" inventory stay sealed, with a known quantity of product inside. Whenever opening a box, scan it's barcode to show that that product is now "in play", along with the amount in the previous box prior to opening.

Bonus points for placing the barcode/qr code on the same spot on the box, facing the hall.

Extra bonus points for placing a camera/scanner on a rail that can then perform the count/scanning for you ;-)

I once wrote some software to automatically figure out what to count (access frequency, value, location, etc), and make the daily count sheets. +1 for cycle count with ABC. Watch out for multiple locations, they can get you.

I once worked somewhere where if R&D needed a part for something, they'd walk out and get it. Guess what that did to the inventory management system... R&D vs production. Fight!

Cycle counting the item when inventory % box size == 0 sounds pretty smart. That's a great way to knock time off counts. I'm curious about worst case stats - under by a small number means there's a mostly full box to be counted.

I wonder about what happens to buffer assisted counting if a new box has to be opened to finish an order. (need 5, 4 left in old pile) Everyone needs to follow the rules, or it all breaks down.

I think if you get the QR codes on boxes, then you just need a robot to run around and scan all the full boxes. :) Sharpie the QR code (leave the mfr bar code) when the box is opened.

If you open a box around the inventory time, just do the inventory before opening the box. Alternatively, if you're opening a box of 1000, taking three, and going rate of them are 300/day, just postpone until they're used up.

So basically, run inventory of a paft when old and loose parts either is or should be zero. If it should be zero, but isn't, adjust inventory if it's low work, wait if it's a lot of work and can be put off (leave a marker to do inventory next time there are only full boxes), and only ever count loose parts if it's severely low turnover (a new box isn't opened in a year, probably rare edge case).

Probably no need to place any codes, almost certainly one on the box as it is.

As far as I can tell, you need to log three things:

Unexpected difference in old stack (should be zero)

Number of boxes in new stack

Barcode (scannable)

Is this the point where I suggest a pen-type barcode reader, hooked to a lilypad over some kind of serial?

Add xbee for live-feed of what needs checking, and reporting back?

If it doesn't fit the infrastructure, I suppose it could be kept separate, and converted to look like a normal count at regular intervals, until time permits a proper update of primary system.

So a couple of days of hacking, and problem gone? (because projects aleays finish on time... ;) )

DIBS on any Geiger tubes you find!!!

ahem Allow me to add some more exclamation points:

!!!!!!!1!!1!!!!eleven!!!! :-)

at a large family owned grocery store i worked at they had a company come in monthly. they started at closing and worked through the night. i ask once about why they used a company, it was cheeper and more accurate. those guys moved a whole lot faster than we would have.

I believe SparkFun did that once, and the results were rather horrible, unfortunately.

Where I work, we used to have to shut down the warehouse for a day or two every year to do inventory. It was very painful one year, when production was trying to build/ship, but couldn't get parts out of the warehouse. It really sucked. After that we started doing cycle counting all year long. It has been very successful. When the auditors come, there is very little interruption. It's a little annoying for the warehouse folks, but has been good overall.

I did find an article about it.

http://www.effectiveinventory.com/article9.html

We've heard a lot of good things about cycle counting, from other warehouses that use it. We're getting things in order to start those so we can get away from the annual physical count.

At my job we never inventory anything ever. So the good news is, we never have to do this. The bad news is, nothing we try to do ever happens in a sane and timely manner.

Ahhh purgatory..... how I loath thee.

Inventory @ a well known BIG BOX warehouse store is one of my most hated times of the year. I always get stuck making sure its being done correctly. It is great when its done and you know where you stand.

I do think this would be a perfect time to think up a new device. I often wondered if it would be feasible to create a inventory tag that is rfid based so your inventory consist of waving a wand over a rack and knowing what is in the rack without having to physically sift through it.

How hard would it be to do?

OR you could have the boxes that are unopened stay sealed & have the # inside written on them, & have the boxes that have their contents being shipped off somewhere be sitting near the shipping area. Then, you would only need to count the shipping area boxes.

we use barcodes :-) they're a bit more reliable.

Most of you are missing the point...all of these things can work, but none of them address all of the issues, what stock do I currently have, whats missing and where is it.

Warehouses, at least the ones the company i work for owns, is pretty organized. The problem is lazy/stupid/thieving packers. When gets picked from, the cartons tend to get moved, sometimes they end up in the wrong location. With larger warehouses that wrong location could be few feet or few hundred feet away. (our warehouse is a mile long!) Another issue is when a packer takes 5 pieces of size 5 and put them in the carton with size 6.

While barcode's do work for the most part, it is not a panacea. There is still a lot of physical work needed to count inventory using barcode's. And it does not help at all to locate shrinkage.

RFID on the other hand could help, but it's till pretty costly to implement. We are currently being forced to use RFID by a major Department store, all told it may cost us at least $100,000 dollars a year minimum, and that's only for the Manufacturer ID (or whats ever its called), this does not include tags or the equipment costs.

They are from the steam age... Rail Road invented bar codes to identify a car. I think there is a better way to do it by now... With bar codes your out of luck if the product falls into the flu space of a rack. Bar codes are good for small numbers of things... but when you have over 100,000 products like a warehouse store it is easy to mess it up and lose 20,000$ worth of product.

worked for a company that was a warehouse store and had thousands of products and it worked fine

Maybe an Arduino-powered abacus next year...? The Arduino would run the LEDs added for style, of course.

Best of luck, guys. I feel your pain. I HATE doing inventories!

now i need to order another arduino chip and a bunch of LEDs :)

The problem with this idea is that we'd have to stick RFID tags on our RFID tags to know how many we had. Unless I misunderstand what you're saying (entirely possible).

I imagine that doing that wouldn't be too expensive (or hard), but:

a) would it be worth the cost?

b1) what if one stopped working?

b2) then SparkFun would have Changing The Batteries Of Our RFID Inventory Tags Day.

I can just see it now...

1,3,many, yes we have that many. :)

I love counting everything but open box nuts and bolts.

http://xkcd.com/764/

Physical counts suck!!! At one of my old jobs, the IT department always had to train and lead the packers through the physical count, and most of them could care less if things were accurate or not. We always would find merchandise in totally incorrect locations, some times in the wrong building...our ware house was huge, about the length of a football field split into three buildings.

But I know its way harder on you guys with those tiny blister packs with identical looking resistors, etc. Way more difficult than counting Jeans and sweaters...

only plus was getting to ride around on the cherry picker!

What if I ordered on monday, will my order be affected?

If you ordered on Monday Oct 31, your order should have already shipped. If you're planning on ordering Monday Nov 7th, there may be a slight delay because we will have a large backlog of orders.

I remember at my last job, we had to do inventory counts every month. It go to be such a pain that I brought in two dozen donuts for all the people that were counting (including me).